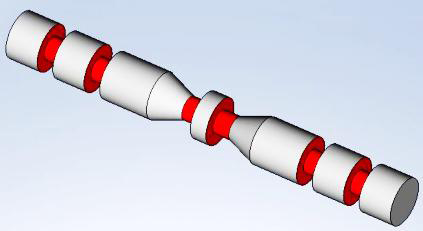

TungCut – Spool Valve – AH725

IMPROVED TOOL LIFE

- Competitor’s poor chip control and re-cutting of chips frequently causes fracture on the cutting edges.

- On the other hand, the chip control of DTE type is highly stable even when machining with 2.5 times higher feed than the competitor, preventing chip re-cutting which is the cause of fracture.

- The sharp cutting edge of DTE type reduces the cutting forces, preventing work deformation and creating fine surface finish.

Share

| Industry | Automotive |

|---|---|

| Component | Spool Valve |

| Material ISO code |

|

| Work material | 12SMn35 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | TungCut |

| TSR No. | 119T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | CTER2020-3T09 | 20X20 shank |

| Insert | DTE3-040 | 2 corner insert |

| Grade | AH725 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 70 | 30 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 80 | 80 |

| Feed f (mm/rev) | 0.1 | 0.04 |

| Coolant | Water soluble | Water soluble |