TriFine – SUS630 Mold – AH725

solved BTA tool regrinding issues by adopting TriFine for precision and stability.

SUS630 stainless steel molds for mask production were being machined in large volumes. The previous solution, BTA brazed tool—required frequent regrinding, creating inefficiencies. By switching to TriFine with a smaller diameter and an insert-type design, the need for regrinding was eliminated, ensuring stable machining. Although higher cutting parameters were possible, the priority was maintaining straightness accuracy and process stability, so existing conditions were kept. This change enabled consistent quality and productivity in mass production.

Share

| Industry | Engineering |

|---|---|

| Component | Mold Base |

| Material ISO code |

|

| Work material | SUS630 |

| Machine(spindle type) | BTA Machine |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | TRI-FINE |

| TSR No. | 5194D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

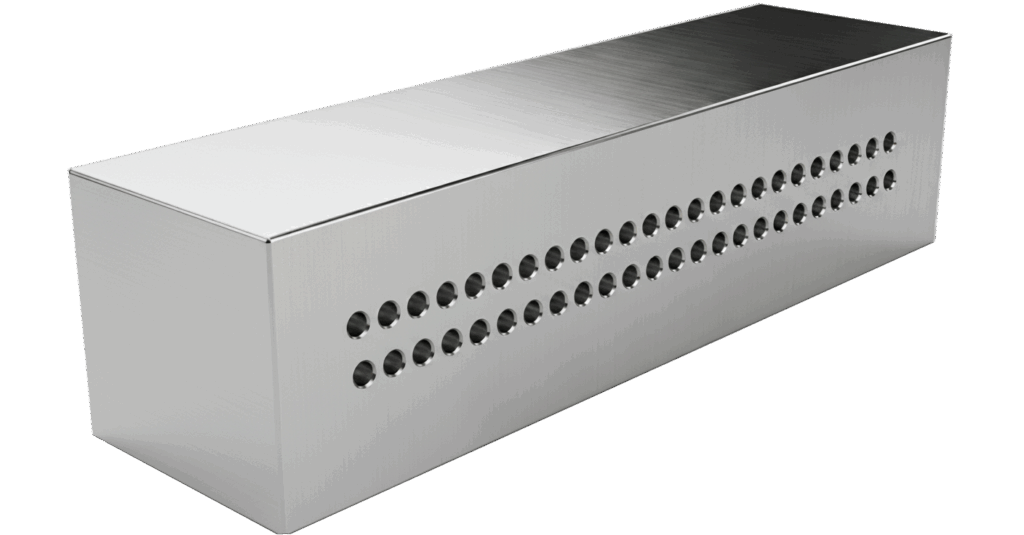

| Body | FNTR-12N-2-15.20 | Brazed Drill |

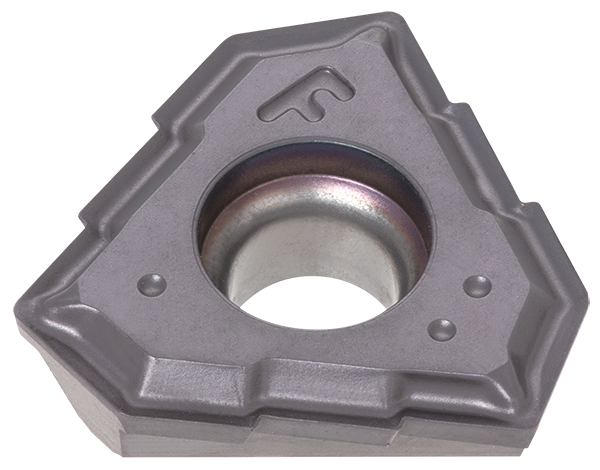

| Insert | TOHT070304R-NDL AH725 | brazed drill |

| Grade | AH725 | PVD coated carbide |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 10.8 | 2.4 |

| Number of workpieces (pcs/insert) | 90 | 20 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 15.20 | 15.20 |

| Hole depth H (mm) | 120 | 120 |

| Cutting speed V/c (m/min) | 60 | 60 |

| Feed f (mm/rev) | 0.02 | 0.02 |

| Feed speed Vf (mm/min) | 25.14 | 25.14 |

| Coolant | oil | oil |