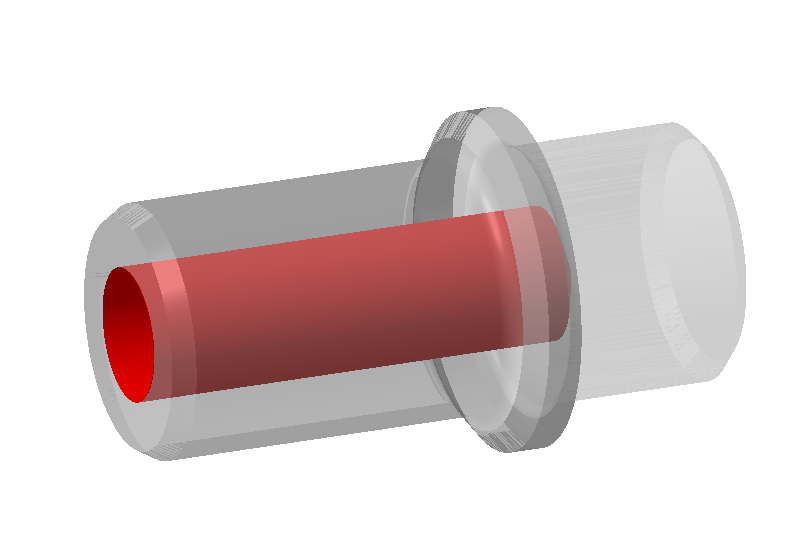

DrillMeister -motor shaft- DMP

IMPROVED TOOL LIFE

In the drilling process for hybrid motor materials, the current tool reached the end of its lifespan before processing 900 units.

Particularly after 500 units, chip contol worsened, leading to frequent machine stoppages.

After switching to DrillMeister, chip management improved, allowing stable processing of 1,000 units.

This significantly reduced machine stoppages caused by chips and improved productivity.

Share

| Industry | Automotive |

|---|---|

| Component | Motor Shaft |

| Material ISO code |

|

| Work material | Carbon steel |

| Machine(spindle type) | CNC Lathe |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillMeister |

| TSR No. | 5377H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TID200F25-5 | Head exchangable drill 5xD |

| Head | DMP205 AH9130 | Drill head |

| Grade | AH9130 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 100 | 90 |

| Number of workpieces (pcs/insert) | 1000 | 900 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 20.5 | 20.5 |

| Hole tolerance grade | IT10 | IT10 |

| Hole depth H (mm) | 100 | 100 |

| Cutting speed V/c (m/min) | 120 | 120 |

| Feed f (mm/rev) | 0.23 | 0.23 |

| Feed speed Vf (mm/min) | 426 | 426 |

| Coolant | Internal coolant | Internal coolant |