TungSixDrill – Flywheel housing – AH7030

IMPROVE TOOL LIFE

With the competitor’s tool, the hole diameter decreased after machining just 50 holes.

In contrast, the latest grade AH7030, which offers excellent wear resistance, effectively prevented both wear and chipping, resulting in improved machining stability.

As a result, twice the tool life was achieved compared to the conventional tool.

Share

| Industry | Automotive |

|---|---|

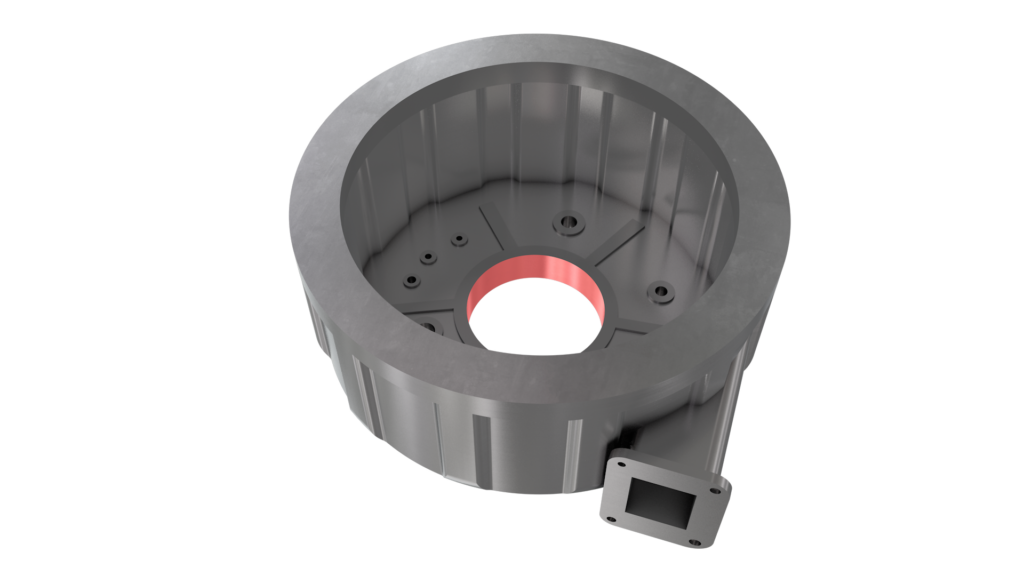

| Component | Flywheel housing |

| Material ISO code |

|

| Work material | FC250/GG25/No30B |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | TungSix-Drill |

| TSR No. | 5206D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TDS280F32-3 | φ28, L/D=3 |

| Insert | WWMU08X408R-DJ | Posi 4corners |

| Grade | AH7030 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Number of workpieces (pcs/insert) | 100 | 50 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 28 | 28 |

| Hole depth H (mm) | 35 | 35 |

| Cutting speed V/c (m/min) | 125 | 125 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Feed speed Vf (mm/min) | 71 | 71 |

| Coolant | Internal | Internal |