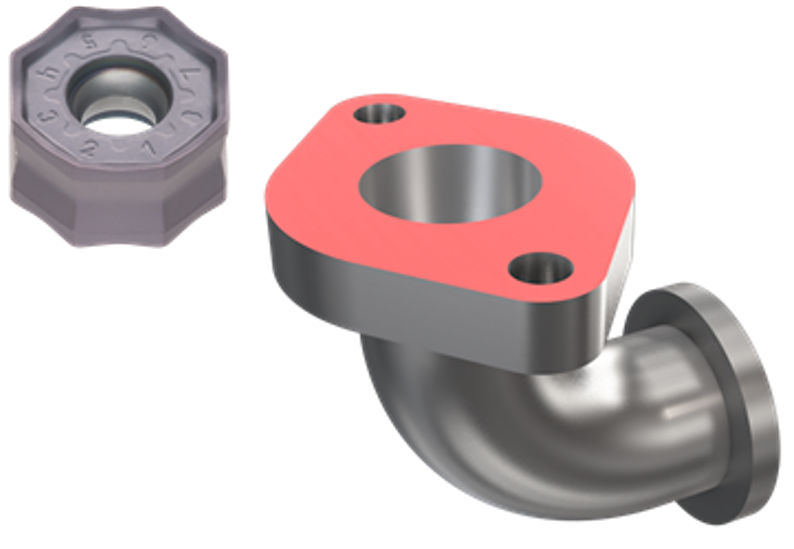

DoTriple-Mill – EGR Cooler Part – AH3135

IMPROVE PRODUCTIVITY & TOOLLIFE

With the competitor’s cutter, hard burrs appeared after machining and had to be removed by hand. Inserts also broke during interrupted cutting, resulting in short and unstable life. DoTriple-Mill -MJ inserts, with sharp edges, eliminated burrs and removed the need for deburring, doubling productivity. The tough AH3135 grade provided 1.5 times longer tool life and prevented breakage.

Share

| Industry | Automotive |

|---|---|

| Component | Stainless Parts |

| Material ISO code |

|

| Work material | SUS304 |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoTriple-Mill |

| TSR No. | 5370M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TASN13J125B38.1R10 | 45 deg. Face mill |

| Number of teeth | 10 | 8 |

| Cutting diameter | 125 | 125 |

| Insert | ONMU0507ANEN-MJ | Octagonal insert, positive |

| Number of cutting edges | 16 | 8 |

| Grade | AH3135 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 200 (656.17 sfm) | 200 (656.17 sfm) |

| Feed per tooth f/z (mm/t) | 0.1 (.004 ipt) | 0.1 (.004 ipt) |

| Feed speed Vf (mm/min) | 509 (20.04 ipm) | 407 (16.02 ipm) |

| Depth of cut ap (mm) | 1.5 (.059") | 1.5 (.059") |

| Width of cut ae (mm) | 100 (3.94") | 100 (3.94") |

| Coolant | External | External |