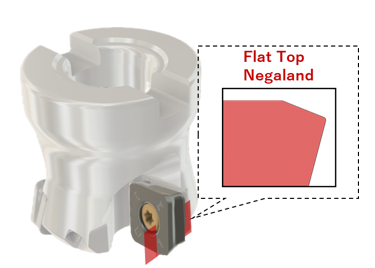

MillQuadFeed15 – Mill scale machining – Flat Top Inserts

IMPROVE TOOLLIFE & PRODUCTIVITY

With the competitor’s tool, only 5 passes were possible per corner. The customer required 15 passes. By using MillQuadFeed Flat Top inserts, stable machining was achieved, tool life increased 3.0 times, and productivity improved by 1.2 times.

Share

| Industry | Engineering |

|---|---|

| Component | Blocks |

| Material ISO code |

|

| Work material | SACM645 |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | High feed milling |

| Product name | MillQuadFeed |

| TSR No. | 5360M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15J100B31.7R06 | High feed cutter |

| Number of teeth | 6 | 5 |

| Cutting diameter | 100 (3.94") | 100 (3.94") |

| Overhang (mm) | 115 (4.53") | 108 (4.25") |

| Insert | SWMW1506USR | Positive inserts |

| Number of cutting edges | 4 | 3 |

| Grade | AH8015 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 70 (230 sfm) | 70 (230 sfm) |

| Feed per tooth f/z (mm/t) | 0.6 (.024 ipt) | 0.6 (.024 ipt) |

| Feed speed Vf (mm/min) | 802 (31.57 ipm) | 668 (26.30 ipm) |

| Depth of cut ap (mm) | 1.0 (.039") | 1.0 (.039") |

| Width of cut ae (mm) | 70 (2.76") | 70 (2.76") |

| Coolant | External coolant | External coolant |