ISO-EcoTurn – Wheel Bearing Hub – T9215

IMPROVED TOOL LIFE

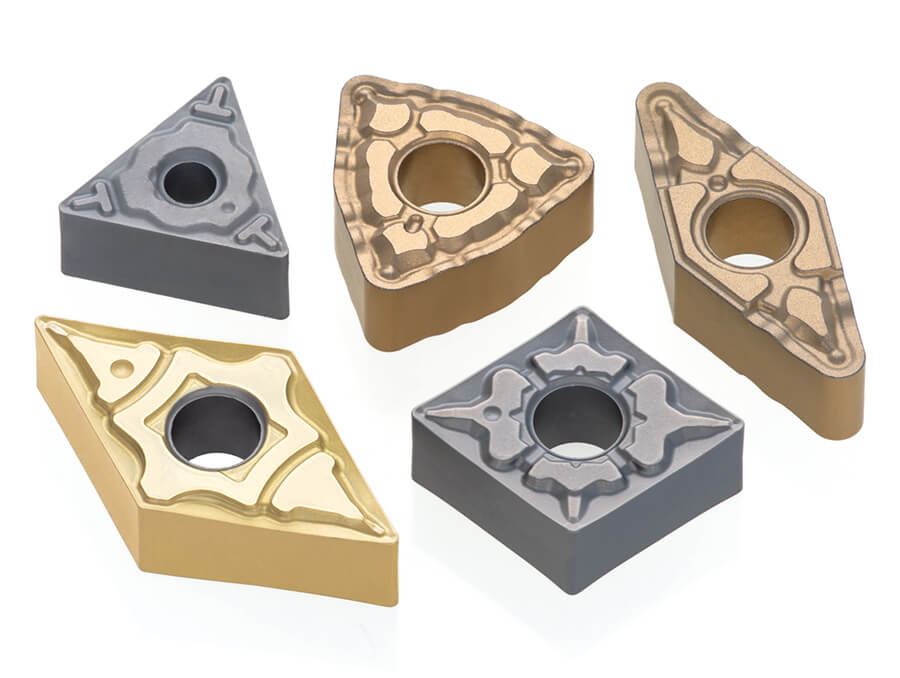

ISO-EcoTurn FNMG insert, featuring a unique insert shape with 45° corner angle, provides larger clearances on the insert sides, facilitating smooth chip evacuation during shoulder facing. The insert eliminated chip re-cutting, while providing 2 times longer tool life. Also, switching from regular-sized DNMG1504 inserts to ISO- EcoTurn FNMG1104 provided significantly reduced cost per

Share

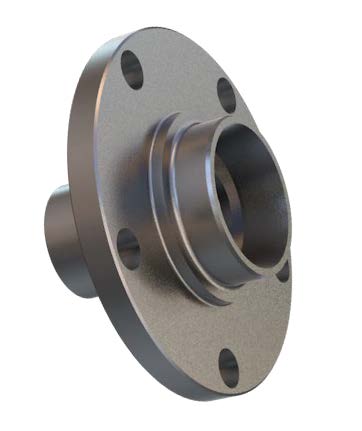

| Industry | Engineering |

|---|---|

| Component | Wheel bearing Hub part |

| Material ISO code |

|

| Work material | S53C |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | ISO-EcoTurn |

| TSR No. | 1655T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | ADQNR2525M1104-A | DDQNR2525M15 |

| Insert | FNMG110412E-TSF | DNMG150412 with medium cutting chipbreaker |

| Grade | T9215 | CVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 150 | 75 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 180 | 180 |

| Feed f (mm/rev) | 0.25 | 0.25 |

| Depth of cut ap (mm) | 0.3 | 0.3 |

| Coolant | Wet | Wet |