ThreadMilling – Manifold Blanket – AH725

IMPROVED PRODUCTIVITY & COST REDUCTION

Tungaloy recommended ThreadMilling, instead of HSS taps. Improvement Result: Improved cycle time by 25% and tool cost by 76%. Tool change time also decreased, reducing machine downtime. This saved additional investments for new machines, which was initially planned. In addition, ThreadMilling tool generated far lower cutting forces, compared with a HSS tap, eliminating the concern for workpiece movement during machining.

Share

| Industry | Automotive |

|---|---|

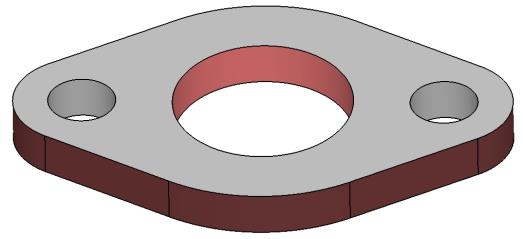

| Component | Manifold Blanket |

| Material ISO code |

|

| Work material | FC250 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Internal threading |

| Product name | ThreadMilling |

| TSR No. | 1642M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | ETTL25M017 W25.0F026R02-PT | HSS tap |

| Insert | TL25SEIR11.5NPT | |

| Grade | AH725 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (mm/min) | 154 | 10 |

| Feed per tooth f/z (mm/t) | 0.095 | 0.095 |

| Feed f (mm/rev) | 0.19 | 0.19 |

| Coolant | External air blast | External air blast |