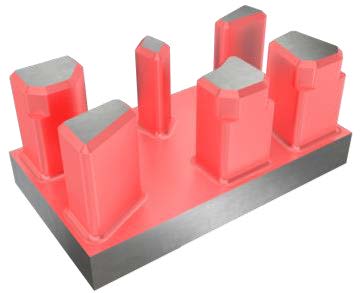

DoFeedTri – Cavity – AH3225

IMPROVED PRODUCTIVITY

DoFeedTri generated low cutting load thanks to the cutting edge with a large rake angle, ensuring reduced vibration and stable machining at increased cutting speed and D.O.C. As a result, 1.5 times higher productivity was achieved. In addition, the number of cutting edges per insert is tripled, reducing cost per edge.

Share

| Industry | Die & Mold |

|---|---|

| Component | Cavity |

| Material ISO code |

|

| Work material | S55C |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Profiling |

| Product name | DoFeedTri |

| TSR No. | 1631M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | HXWX03M025M12R04 | High feed cutter |

| Number of teeth | 4 | 2 |

| Cutting diameter | 25 | 25 |

| Insert | WXMU0303ZER-MM | Positive inserts |

| Number of cutting edges | 6 | 2 |

| Grade | AH3225 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 157 | 110 |

| Feed per tooth f/z (mm/t) | 0.75 | 1.5 |

| Feed speed Vf (mm/min) | 6000 | 4200 |

| Depth of cut ap (mm) | 0.5 | 0.4 |

| Width of cut ae (mm) | 20 | 20 |

| Coolant | Air | Air |