Improved tool setup time

Improved tool setup time by TUNGHYDRO

The long drill setup was time-consuming, and reducing machine downtime was an issue. In particular, a lot of time was required to achieve a runout accuracy of 5 µm for long protrusion tools.

By proposing the Hydro Holder, which can clamp tools only by tightening screws, high-precision mounting became possible, and the tool setup time was significantly reduced from 10 minutes to 0.5 minutes.

This has reduced machine downtime and realized more efficient machining.

Share

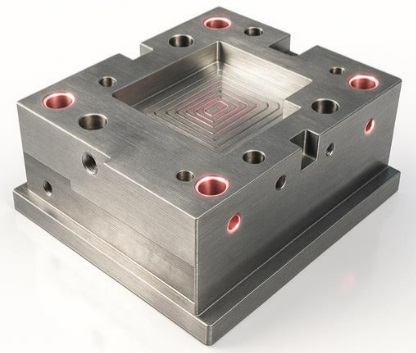

| Industry | Die & Mold |

|---|---|

| Component | Mold |

| Material ISO code |

|

| Work material | C55 |

| Machine(spindle type) | Dedicated Machine |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | TungHold |

| TSR No. | 5243D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | BT40HYDRO6X90T | BT40 holder |

| Head | DSW051-120-06I20 | DSW051-120-06I20 |

| Grade | AH725 | AH725 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 6 | 6 |

| Coolant | Internal | Internal |