TungBoreMini – Machine parts – AH725

IMPROVED PROCESS TIME

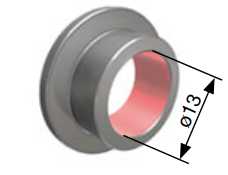

Traditionally, machining a Ø13 hole required three different tools—a leading drill, an Ø8 drill, and a boring tool.

By switching to the TungBoreMini, all operations were consolidated into a single tool, eliminating tool changes and helping to reduce the cycle time of the machining process.

Share

| Industry | Engineering |

|---|---|

| Component | Machine Parts |

| Material ISO code |

|

| Work material | S45C/C45 |

| Machine(spindle type) | Swiss Lathe |

| Tool family | Turning |

| Tool category | Internal turning |

| Product name | TungBoreMini |

| TSR No. | 5241T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | A07080-TBMRF-2.25 | φ8 ID tool |

| Insert | XCMT040102R-PS | CCGT06 |

| Edges par insert | 2 | 2 |

| Cutting width | 3 | 3 |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 120 | 120 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth of cut ap (mm) | 0.5-2 | 0.5-2 |

| Coolant | Wet | Wet |