DrillForceMeister – H beam – AH725

IMPROVE TOOL LIFE

We applied our SMP geometry of DrillForceMeister and as a result tool life was increased by 1.25 times.

Thanks to our strong head clamp system, machining reliability for Material that causes machining vibration like H beam has improved.

Both improvements resulted a reduction of the cost per hole by 60%.

Share

| Industry | Heavy |

|---|---|

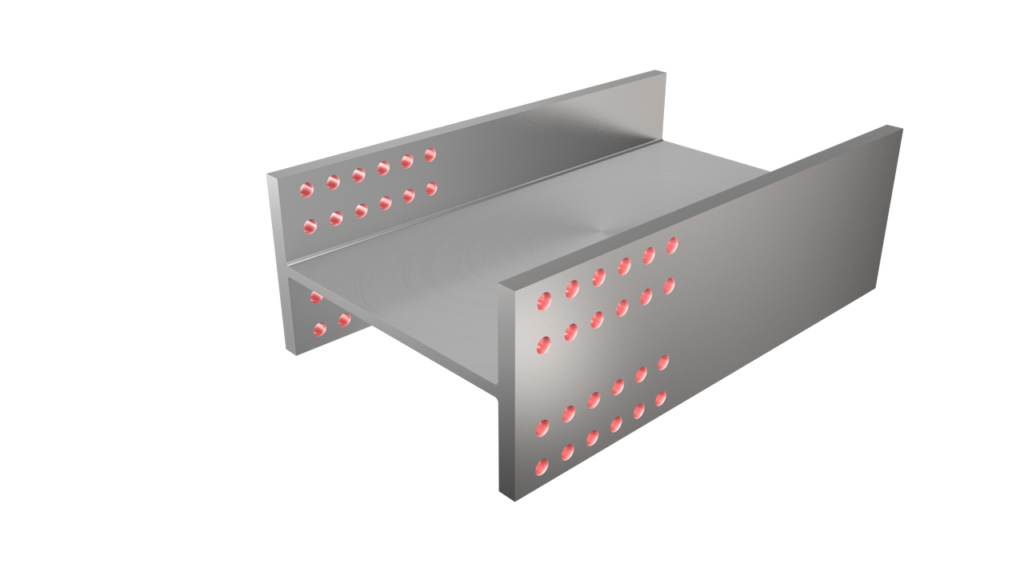

| Component | H Beam |

| Material ISO code |

|

| Work material | SN49B |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillForce-Meister |

| TSR No. | 1215D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TIS260F32-3 | Solid drill |

| Head | SMP260 | - |

| Grade | AH725 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 154 | 123.2 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 26 | 26 |

| Hole depth H (mm) | 44 | 44 |

| Cutting speed V/c (m/min) | 85 | 85 |

| Feed f (mm/rev) | 0.25 | 0.25 |

| Feed speed Vf (mm/min) | 260 | 260 |

| Coolant | MQL | MQL |