DrillForceMeister –Mold– AH725

IMPROVE TOOL LIFE

The robust head clamp and high-rigidity body design of the DrillForceMeister contribute to achieving long toollife compared to competitors' products.

In addition, the use of head-changeable drills eliminated the need for re-grinding.

Easier tool management because there is no need to modify the machine program after regrinding and only new drill head needs to be replaced.

Share

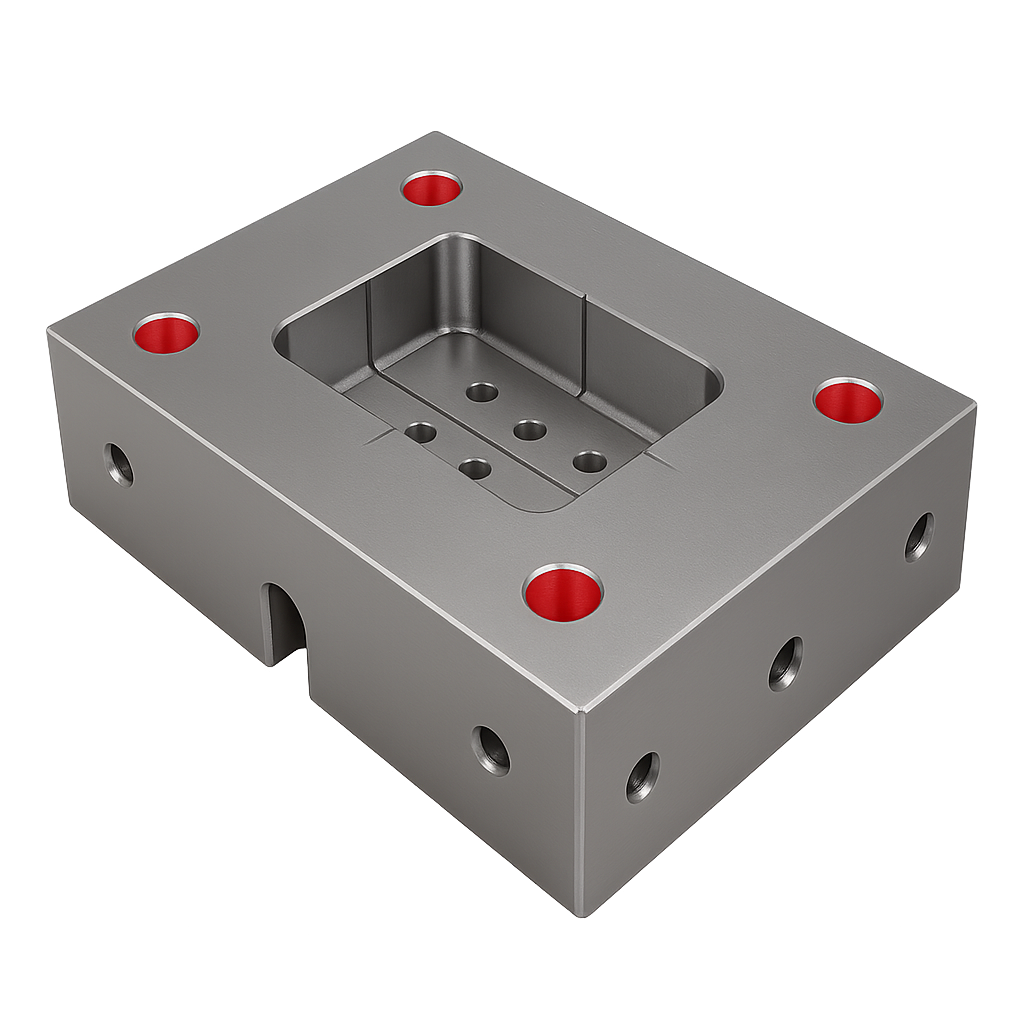

| Industry | Die & Mold |

|---|---|

| Component | Mold |

| Material ISO code |

|

| Work material | S55C |

| Machine(spindle type) | Horizontal Machining Center Middle(#40,HSK63) |

| Tool family | Holemaking |

| Tool category | Drilling |

| Product name | DrillForce-Meister |

| TSR No. | 5195D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TIS200F25-5 | Solid drill |

| Head | SMP200 AH725 | ー |

| Grade | AH725 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 64 | 48 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 20 | 20 |

| Hole depth H (mm) | 80 | 80 |

| Cutting speed V/c (m/min) | 90 | 90 |

| Feed f (mm/rev) | 0.2 | 0.2 |

| Feed speed Vf (mm/min) | 286 | 286 |

| Coolant | Internal+External Coolant | Internal+External Coolant |