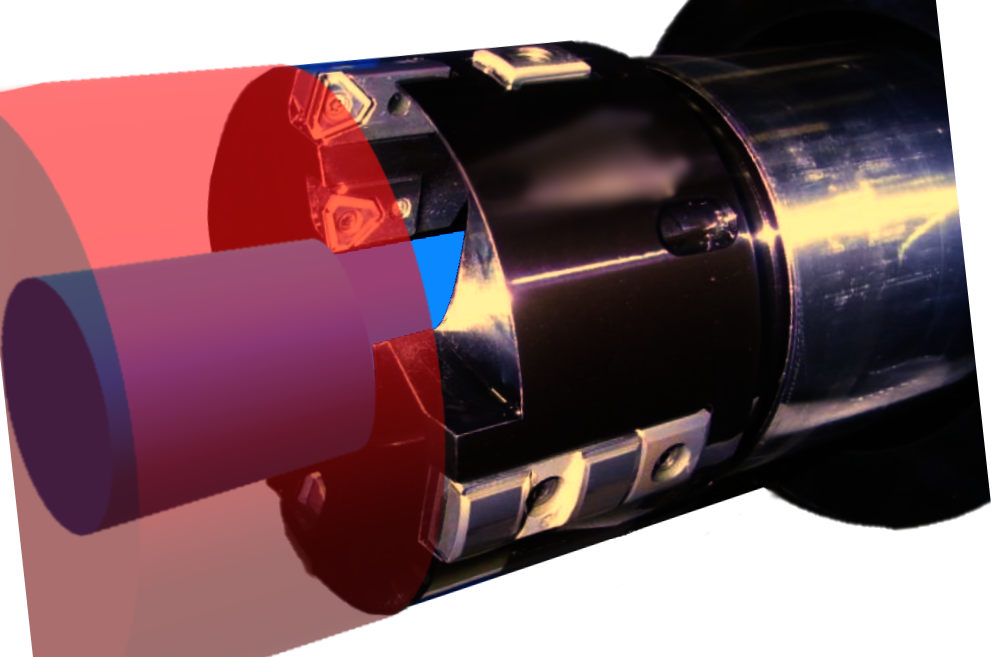

BTA – Breaker Body – Trepaning BTA head

IMPROVE TOOL LIFE

BTA Trepan improved the applicaiton by adjusting the core inner diameter to ø70.

Competitor tool produced entangled chips and was prone to chipping. after drilling the core was easy to get stuck.

UTT trepan heads solved all the issues and doubled insert life per corner thanks for chip braker.

Share

| Industry | Engineering |

|---|---|

| Component | Breaker |

| Material ISO code |

|

| Work material | SCM435 |

| Machine(spindle type) | BTA Machine |

| Tool family | Holemaking |

| Tool category | Deep hole drilling |

| Product name | BTA |

| TSR No. | 5298D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | UTT130-148.00 | Trepan drill |

| Insert | TPMX240512R | special insert |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 3 | 1.5 |

| Number of workpieces (pcs/insert) | 2 | 1 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 148 | 148 |

| Hole depth H (mm) | 1500 | 1500 |

| Cutting speed V/c (m/min) | 60 | 47 |

| Feed f (mm/rev) | 0.25 | 0.39 |

| Feed speed Vf (mm/min) | 32 | 39 |