SwissBore – Motorcycle parts – SH7025

IMPROVED PROCESS TIME

For finishing boring of aluminum alloy motorcycle parts, a dial-adjustable boring cutter was traditionally used, which required significant time for adjusting the finished hole diameter.

By introducing the **SwissBore** digital diameter adjustment mechanism, rapid fine-tuning of the finished diameter became possible, reducing machine downtime and contributing to improved machine utilization rates.

Share

| Industry | Automotive |

|---|---|

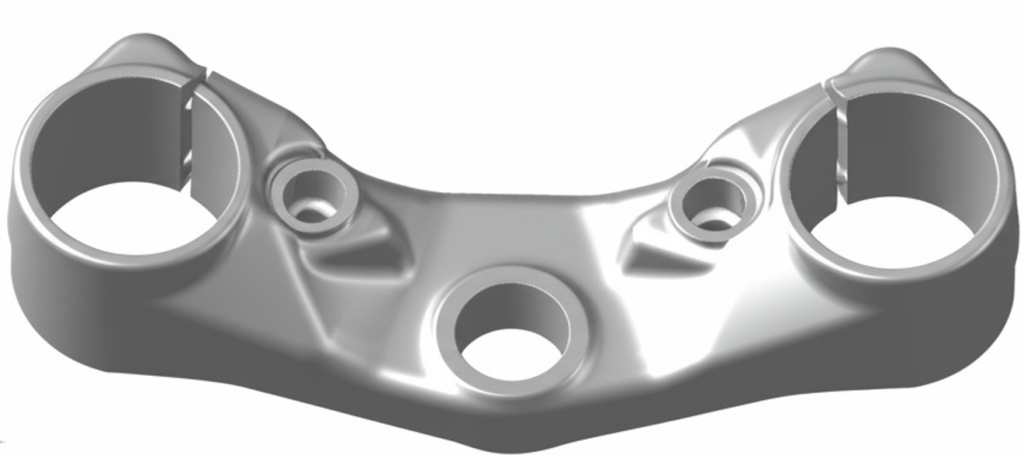

| Component | Motorcycle parts |

| Material ISO code |

|

| Work material | A2014 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Holemaking |

| Tool category | Internal boring |

| Product name | SwissBore |

| TSR No. | 5175H |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | 305.039.051.057 | boring head |

| Insert | CCGT060204FN-JS | CCGT06type |

| Grade | SH7025 | carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 40.01 | 40.01 |

| Hole depth H (mm) | 30 | 30 |

| Cutting speed V/c (m/min) | 1000 | 300 |

| Feed f (mm/rev) | 0.2 | 0.2 |

| Feed speed Vf (mm/min) | 1990 | 597 |

| Coolant | wet(External) | wet(External) |