Increase Productivity with DeepTriDrill

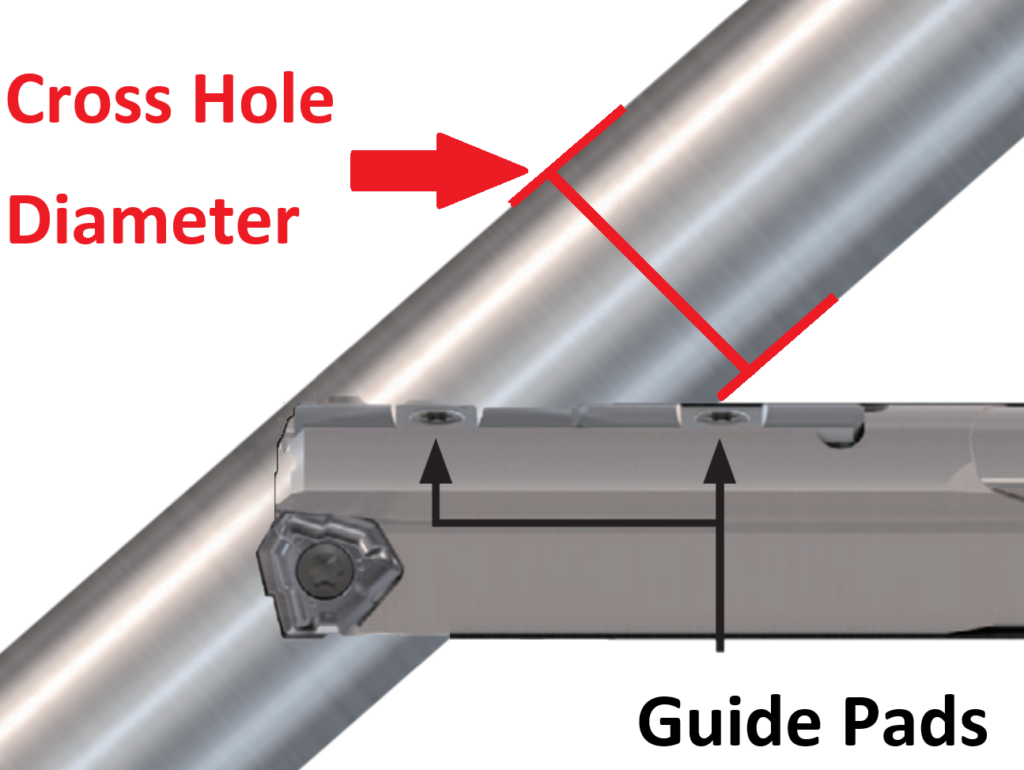

DeepTriDrill resolved a problematic cross hole operation, offering exceptional productivity improvements.

By switching from the traditional Spade drill to DeepTriDrill with 2 rows of guide pads, customers have experienced a significant reduction in cycle time, tool breakage and machine downtime.

The advanced cutting parameters of DeepTriDrill—spindle speed of 1200 RPM, cutting speed of 54 mm/min, and feed rate of 70 mm/min—have proven to be much more efficient compared to the previous setup.

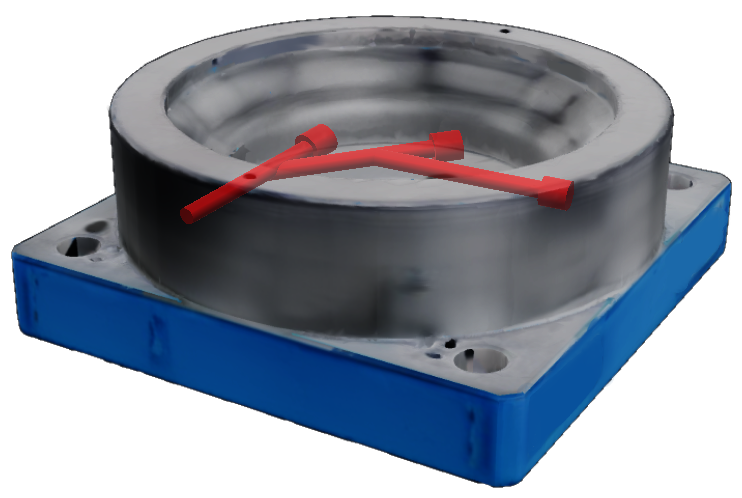

This solution not only enhances the reliability of the drilling process but also boosts productivity by 3.5 times, making it an ideal choice for machining pre-hardened steel in die casting molds.