TungCut – Sleeve pin guide – SUJ2

IMPROVED TOOL LIFE and PRODUCTION COST

For the parting off of the sleeve pin guide, the customer had been using 2mm wide inserts.

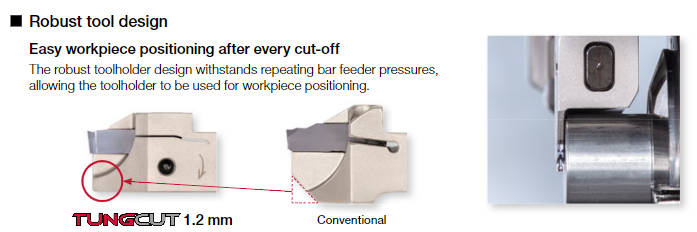

Tungaloy proposed using TungCut’s 1.2mm wide inserts for this process. Despite being thin, TungCut, with its high holder rigidity, achieved stable parting off and extended tool life by 1.5 times.

Additionally, the reduced insert width led to a decrease in the annual usage of bar material, resulting in an annual material cost savings of $100,000.

Share

| Industry | Automotive |

|---|---|

| Component | Sleeve pin guide |

| Material ISO code |

|

| Work material | SUJ2 |

| Machine(spindle type) | Swiss Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | TungCut |

| TSR No. | 5039T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | JTTEL1212F1.2D16 | 12x12 shank |

| Insert | DGS1.2-003 | 2mm width insert |

| Edges par insert | 2 | 2 |

| Cutting width | 1.2 | 2 |

| Grade | AH725 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 1500 | 1000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed f (mm/rev) | 0.03 | 0.03 |

| Depth (mm) | 3.75 | 3.75 |

| Coolant | wet | wet |