TungMeister – 2 Wheel Crank Shaft – AH735

IMPROVED PRODUCTIVITY AND TOOL LIFE

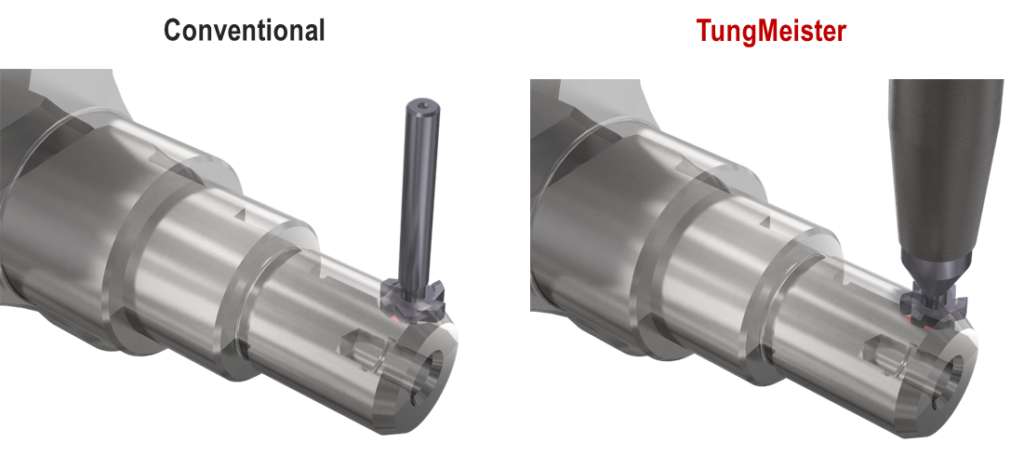

For the crescent key machining of motorcycle crankshafts, the conventional tool used was a 12-flute T-slot cutter, but chatter was a significant issue.

To improve chatter resistance, we proposed using the TungMeister T-slot head. By reducing the number of cutting edges from 12 to 6, we were able to suppress chatter.

As a result, we achieved a 9 times productivity and 3 times longer tool life.

Share

| Industry | Automotive |

|---|---|

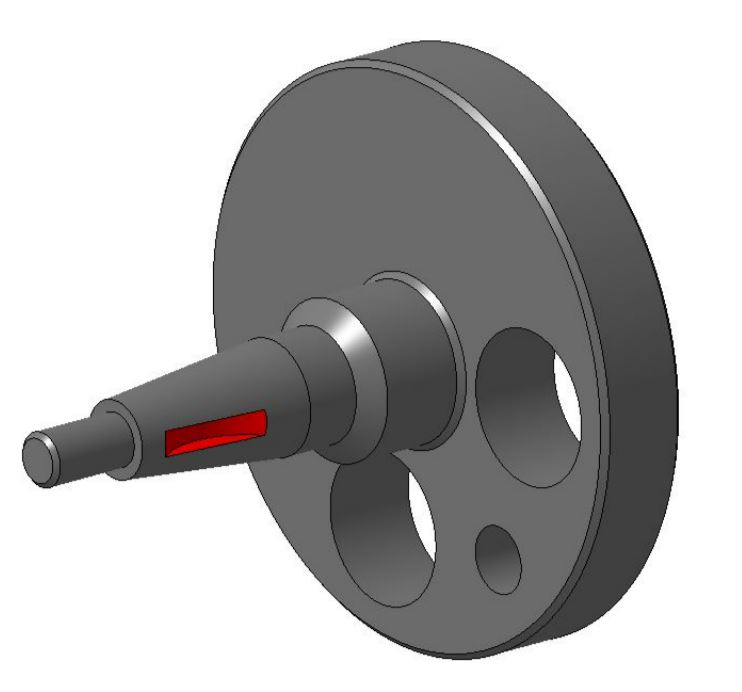

| Component | 2 Wheel crank shaft |

| Material ISO code |

|

| Work material | SCM435 |

| Machine(spindle type) | Multi-Tasking Machine |

| Tool family | Milling |

| Tool category | Slotting |

| Product name | TungMeister |

| TSR No. | 5037M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | VSSD16L090S10-W-A | Steel shank |

| Effective number of teeth | 6 | 12 |

| Cutting diameter | 26 | 26 |

| Overhang (mm) | 25 | 25 |

| Insert | VST26W4.00R02-6S10 | Φ26 head |

| Number of cutting edges | 1 | 1 |

| Grade | AH735 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 41 |

| Feed per tooth f/z (mm/t) | 0.03 | 0.004 |

| Feed speed Vf (mm/min) | 221 | 25 |

| Depth of cut ap (mm) | 4 | 4 |

| Width of cut ae (mm) | 5 | 5 |

| Coolant | Dry | Dry |