AH905 – Aerospace Parts – AH905

IMPROVED TOOL LIFE

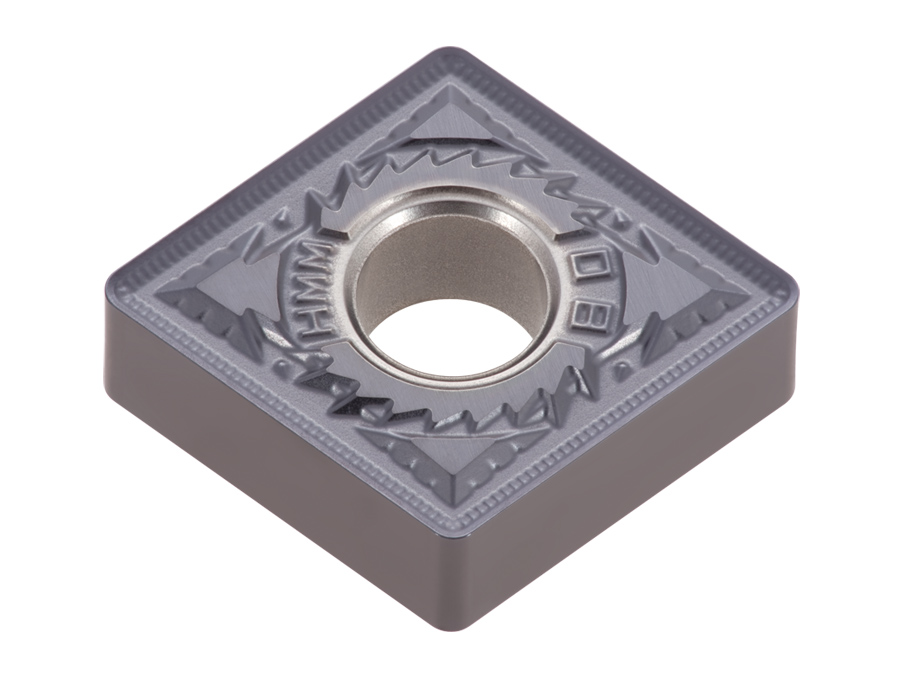

Low cutting force -Sharp land design and unique dots on rake face significantly achieves low cutting force by reducing contact area to chip. HMM chipbreaker offers highly stable chip control. -

Stable tool life -AH905, an ideal grade for superalloy turning, offers stable machining even of the difficult-to-cut materials, which achieves 1.3 times longer tool life than the competitor. This is the best solution for superalloy machining!

Share

| Industry | Aerospace |

|---|---|

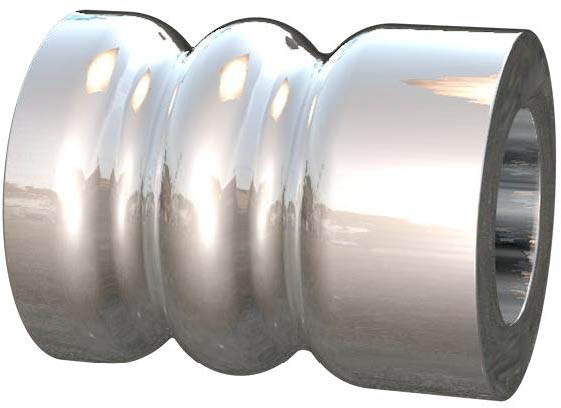

| Component | Aerospace part |

| Material ISO code |

|

| Work material | Inconel 718 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | AH905 |

| TSR No. | 310T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | AVJNR/L2020K16-A | AVJNR/L2020K16-A |

| Insert | VNMG160408-HMM | VNMG160408-Finish chip breaker |

| Grade | AH905 | PVD(S05) |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 8 | 6 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 50 | 50 |

| Feed f (mm/rev) | 0.2 | 0.2 |

| Depth of cut ap (mm) | 1 | 1 |

| Coolant | Water soluble | Water soluble |