DoTwist-Ball – Slide Core – AH3135

IMPROVED PRODUCTIVITY

High productivity

-Competitor’s cutter could not increase feed rate because its cutting edge was not tough enough to machine HRC40 material in higher feed rate. DoTwist-Ball could machine the workpiece without chipping in high feed rate because the cutting edge had a big corner radius and tough grade

Share

| Industry | Die & Mold |

|---|---|

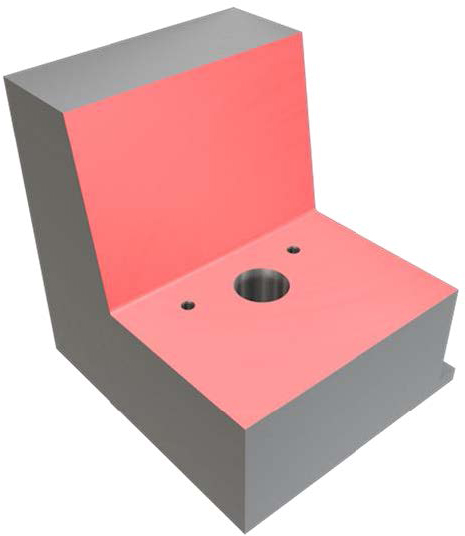

| Component | Slide Core |

| Material ISO code |

|

| Work material | NAK80 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | DoTwistBall |

| TSR No. | 572M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EXLN04M025C25.0R03 | Shoulder milling cutter |

| Effective number of teeth | 3 | 2 |

| Cutting diameter | 25 | 25 |

| Insert | LNMX0405R4-MJ | 2 corner type positive insert |

| Number of cutting edges | 4 | 2 |

| Grade | AH3135 | PVD(P15) |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 | 150 |

| Feed per tooth f/z (mm/t) | 0.3 | 0.15 |

| Feed speed Vf (mm/min) | 1719 | 573 |

| Depth of cut ap (mm) | 4 | 5 |

| Width of cut ae (mm) | 7 | 5 |

| Coolant | External | External |