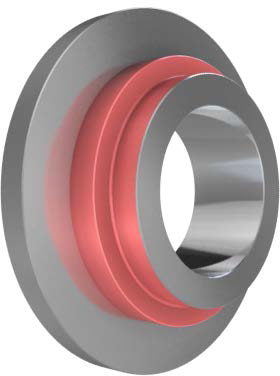

SW and FW – Outer Race – T9225

COST REDUCTION

Drastic cost reduction

- The reduction in tool cost with SW chipbreaker was about 80% compared to the competitor’s wiper insert due to the following improvements.

1. Doubled tool life

2. Reduced tool cost by using ISO-EcoTurn

3. Increase in the number of corners per insert by choosing the insert shape suitable for the operation

Improved productivity

- SW chipbreaker with the wiper edge in the innovative geometry allowed the cutting conditions to be optimized for the operation, increasing

productivity by 1.2 times.

Share

| Industry | Automotive |

|---|---|

| Component | Outer Race |

| Material ISO code |

|

| Work material | S45C |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | Face turning |

| Product name | SW and FW |

| TSR No. | 555T |

Tool

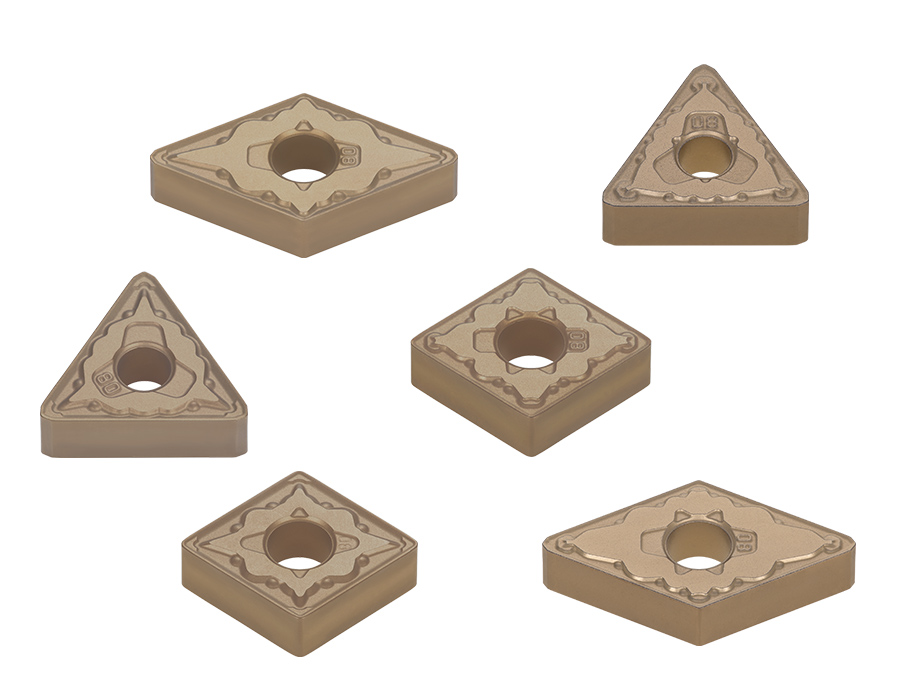

| Tungaloy | Competitor | |

|---|---|---|

| Holder | AWLNR2525M0604-A | DDJNR2525M15 |

| Insert | WNMG060412E-SW | DNMG150412-Medium chip breaker |

| Edges par insert | 6 | 4 |

| Grade | T9225 | CVD(P25) |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 260 | 330 |

| Feed f (mm/rev) | 0.45 | 0.3 |

| Depth of cut ap (mm) | 1.5 | 1.5 |

| Coolant | wet | wet |