MillQuadFeed15 – Forging Die – AH3135

IMPROVED PRODUCTIVITY

In Machining of Forging Die Refurbishing. High Productivity. MillQuadFeed’s capability for a large depth of cut reduced the number of passes required, thus improving metal removal by 2.1 times against the competition. MillQuadFeed’s robust cutting edge eliminates instability concerns in machining extremely hard surface of forging die.

Share

| Industry | Die & Mold |

|---|---|

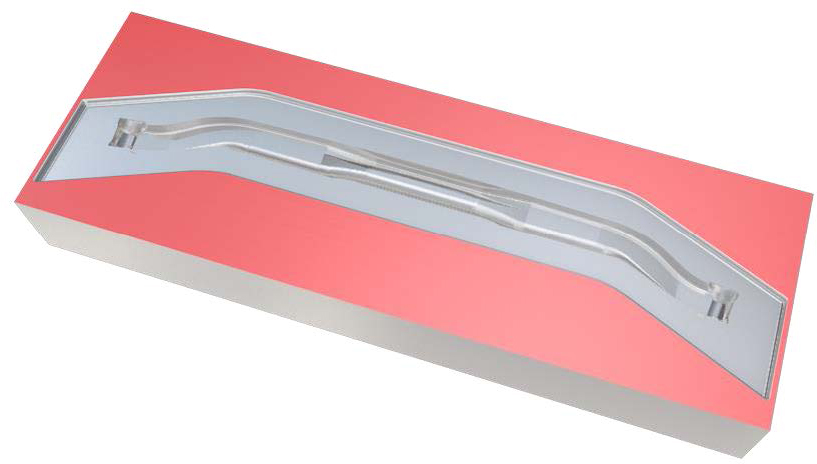

| Component | Forging Die |

| Material ISO code |

|

| Work material | SKT4/55NiCrMoV7 |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | MillQuadFeed |

| TSR No. | 534M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15J100B31.7R06 | High feed cutter |

| Effective number of teeth | 6 | 6 |

| Cutting diameter | 100 | 100 |

| Insert | SWMT1506ZER-MJ | W type insert |

| Number of cutting edges | 4 | 3 |

| Grade | AH3135 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 100 | 100 |

| Feed per tooth f/z (mm/t) | 0.4 | 0.33 |

| Feed speed Vf (mm/min) | 763 | 600 |

| Depth of cut ap (mm) | 2.5 | 1.5 |

| Width of cut ae (mm) | 70 | 70 |

| Coolant | Air | Air |