SW and FW – Shaft Parts – T9225

IMPROVED PRODUCTIVITY

Improved productivity

- FW chipbreaker has new wiper edge shape and unique “Two-Stage Protrusion” design, which extends productivity by 1.3 times compared to the competitor!

Stable machining

- The competitor starts to produce long chips due to increased crater wear when the number of machined units reaches around 20. The combination of the versatile CVD grade T9215 and FW chipbreaker prevents crater wear and provides stable chip control, extending tool life by 2 times compared to the competitor.

Share

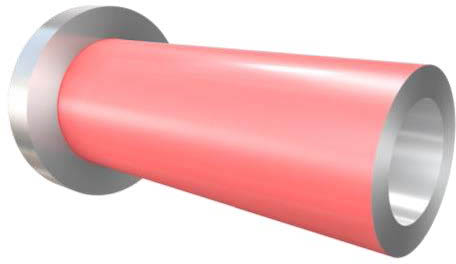

| Industry | Automotive |

|---|---|

| Component | Shaft Parts |

| Material ISO code |

|

| Work material | SS400 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | SW and FW |

| TSR No. | 478T |

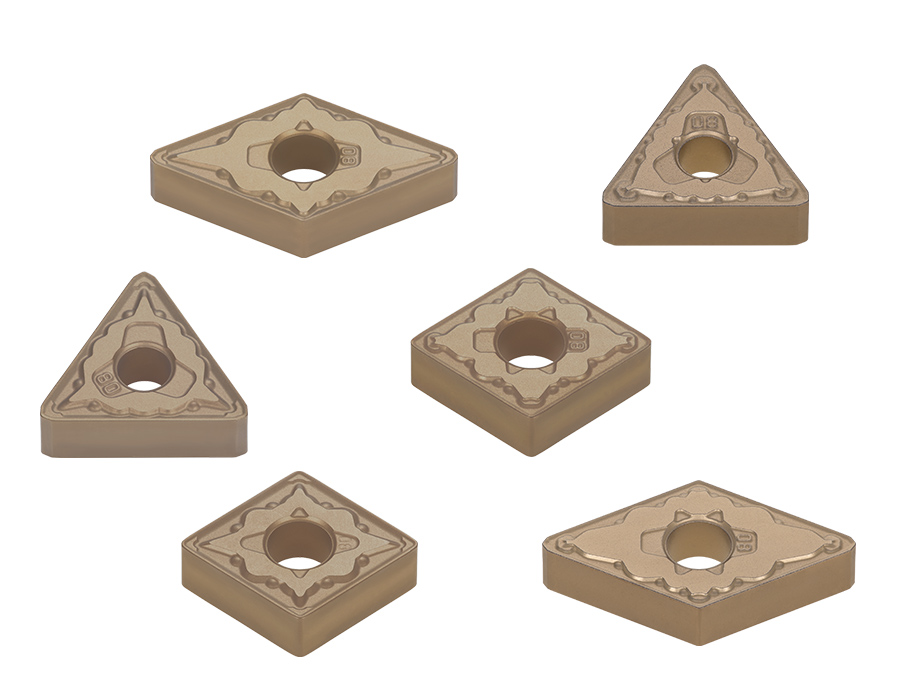

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | AWLNL2525M06 | AWLNL2525M06 |

| Insert | WNMG060408E-FW | WNMG060408-Medium chip breaker |

| Grade | T9215 | CVD(P15) |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 40 | 20 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 350 | 350 |

| Feed f (mm/rev) | 0.4 | 0.3 |

| Depth of cut ap (mm) | 0.5 | 0.5 |

| Coolant | wet | wet |