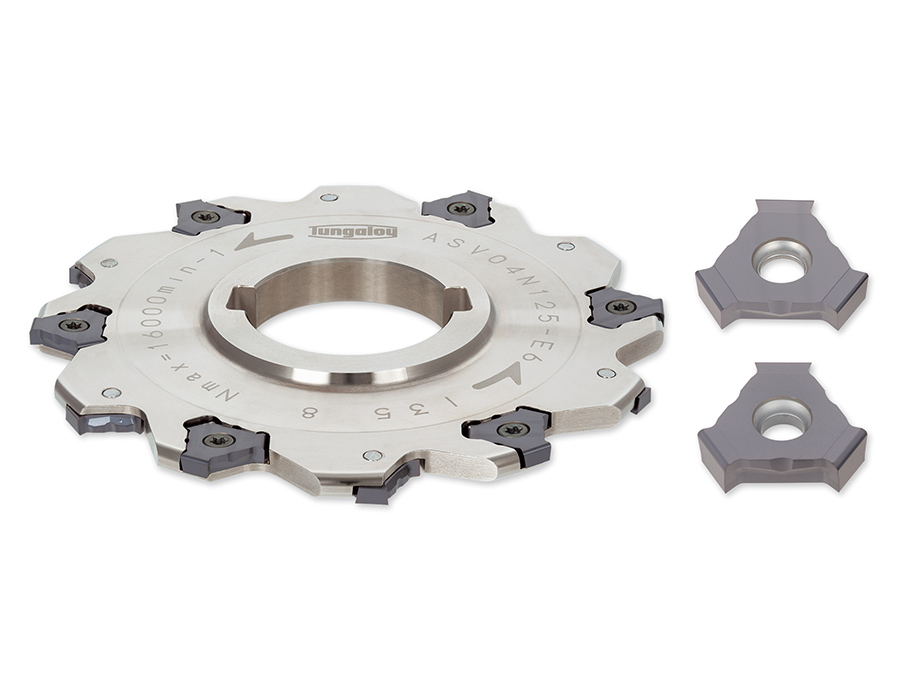

TungThinSlit – Knuckle – AH725

IMPROVED PRODUCTIVITY AND TOOL LIFE

Higher productivity

- Flex slot milling is a vibration-prone application due to non-rigid clamping. Positive geometry of TungThinSlit not only reduced vibration but also improved productivity by 3 times.

Long tool life

- Tool life/cutting edge also increased by 40% as the TungThinSlit insert has 6 cutting edges while the competitor has only 4.

Share

| Industry | Automotive |

|---|---|

| Component | Knuckle |

| Material ISO code |

|

| Work material | 41CrS4 |

| Machine(spindle type) | Vertical Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Slotting |

| Product name | TungThinSlit |

| TSR No. | 456M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | ASV02N125-E4 | Side cutter |

| Effective number of teeth | 5 | 8 |

| Cutting diameter | 125 | 125 |

| Insert | TVKX020204TN-MJ | 4 corner insert |

| Number of cutting edges | 6 | 4 |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 | 150 |

| Feed per tooth f/z (mm/t) | 0.1 | 0.05 |

| Feed speed Vf (mm/min) | 300 | 100 |

| Depth of cut ap (mm) | 4 | 4 |

| Width of cut ae (mm) | 30 | 30 |

| Coolant | Wet | Wet |