BallFinishNose – Mold for Automotive Parts – AH710

IMPROVED TOOL LIFE

Consistent & long tool life

- With AH710 – the most suitable grade for milling hard steels, the tool life increased by 1.3 fold. BallFinishNose’s unique coolant delivery system offered good surface finishand appearance.

Share

| Industry | Die & Mold |

|---|---|

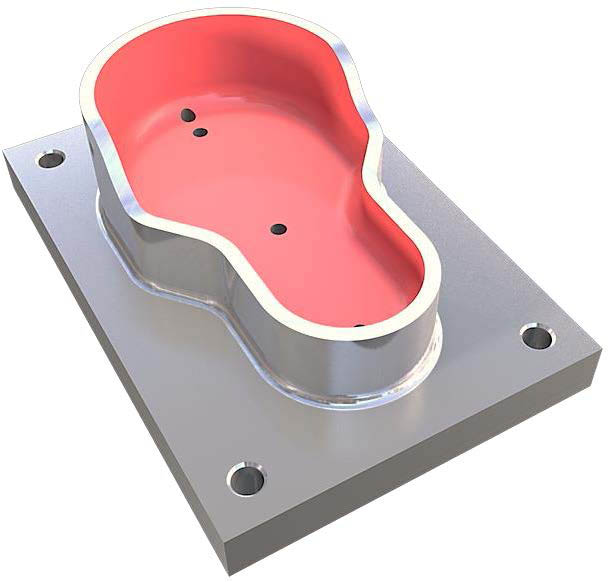

| Component | Mold for Automotive Parts |

| Material ISO code |

|

| Work material | SKD11 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Profiling |

| Product name | BallFinishNose |

| TSR No. | 442M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EBFM20S20C220 | Ball type insert cutter |

| Effective number of teeth | 2 | 2 |

| Cutting diameter | 20 | 20 |

| Insert | ZFBM200R00-MJ | ø20 blade type insert |

| Grade | AH710 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 283 | 283 |

| Feed per tooth f/z (mm/t) | 0.39 | 0.39 |

| Feed speed Vf (mm/min) | 3513 | 3513 |

| Depth of cut ap (mm) | 0.15 | 0.15 |

| Width of cut ae (mm) | 0.8 | 0.8 |

| Coolant | Internal | Internal |