TinyMini-Turn – Sleeve – SH730

IMPROVED PRODUCTIVITY

High productivity

- Conventionally, the customer machined the part at low cutting speed due to the problem with chip control. With TinyMini-Turn, internal coolant supply allows increased cutting speed, leading to the reduction in machining time by 41%.

Good surface quality

- TinyMini-Turn improved surface quality and accuracy in dimension of machined parts compared to the conventional tool because TinyMini-Turn has sharp cutting edges.

Share

| Industry | Miniature |

|---|---|

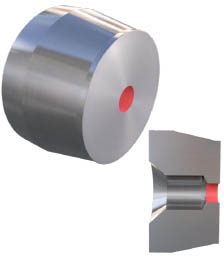

| Component | Sleeve |

| Material ISO code |

|

| Work material | SCM415H |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | Boring |

| Product name | TinyMini-Turn |

| TSR No. | 410T |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | JBBS25-4-L100C | ø16 shank |

| Insert | JBTR04230010-D040 | ø4 Solid bar |

| Grade | SH730 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 34 | 20 |

| Feed f (mm/rev) | 0.05 | 0.05 |

| Depth of cut ap (mm) | 0.1 | 0.1 |

| Coolant | External: oil | External: oil |