TungAluMill – Pressure Vessel Pan – TH10

MINIMIZED BENDING OF WORKPIECE

Minimized bending of workpiece

– TungAluMill’s sharp cutting edge generates minimum thrust force, thus reducing the bending of the plate by 1/5 compared to competitor tool. In addition, burr isminimized.

Good surface finish

– Polished and sharp wiper edge improves machined surface.

Share

| Industry | Automotive |

|---|---|

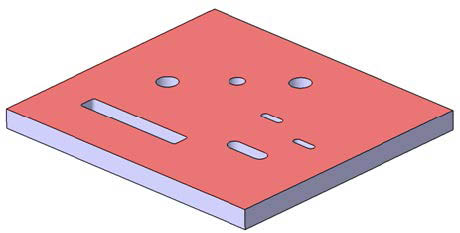

| Component | Pressure Vessel Pan |

| Material ISO code |

|

| Work material | 5083 |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | TungAluMill |

| TSR No. | 337M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TPV16R063M22.0E05 | Face milling cutter |

| Effective number of teeth | 5 | 5 |

| Cutting diameter | 63 | 63 |

| Insert | XVCT160512R-AJ | 4 corner positive insert |

| Number of cutting edges | 2 | 4 |

| Grade | TH10 | Non coated carbide |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 900 | 470 |

| Feed per tooth f/z (mm/t) | 0.25 | 0.2 |

| Feed speed Vf (mm/min) | 5700 | 4500 |

| Depth of cut ap (mm) | 1.2 | 1.2 |

| Coolant | Wet (External) | Wet (External) |