Tung-Tri – Main Frame – AH3135

REDUCED MACHINING TIME & DOWN TIME

Machining time is reduced

-Tung-Tri machined the workpiece with triple D.O.C. compared to competitors, due to low cutting force rake geometry and anti-chatter feature.

Cleaning time is also reduced

- The customer was cleaning the workpiece after every pass to avoid chips interfering during the second pass. Since Tung-Tri could machine the component in just 1 pass, so cleaning time is reduced.

Share

| Industry | Heavy |

|---|---|

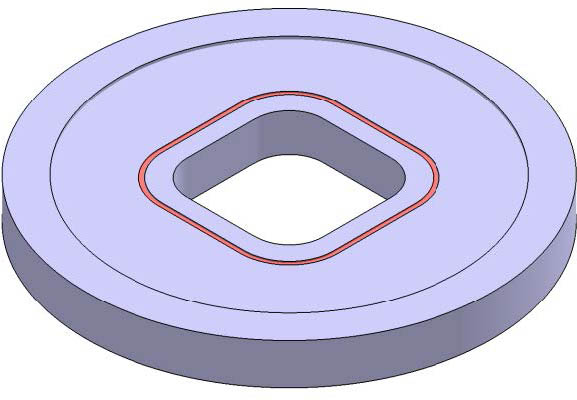

| Component | Main Frame |

| Material ISO code |

|

| Work material | Hiten 50 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Slotting |

| Product name | Tung-Tri |

| TSR No. | 319M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | EPA10R032M32.0-03N | ø3 |

| Effective number of teeth | 3 | 2 |

| Cutting diameter | 32 | 32 |

| Insert | TOMT100408PDPR-MJ | 2 corner positive insert |

| Number of cutting edges | 3 | 2 |

| Grade | AH3135 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 120 | 120 |

| Feed per tooth f/z (mm/t) | 0.06 | 0.13 |

| Feed speed Vf (mm/min) | 215 | 310 |

| Depth of cut ap (mm) | 8 X1 | 2.7 x 3 |

| Width of cut ae (mm) | 32 | 32 |

| Coolant | Wet (external) | Wet (external) |