DoPent – Bracket – T1215

Incredibly high productivity

DoPent’s low cutting force geometry allows machining with bigger width of cut “ae” and double feed rate compared to conventional cutter even on unstable component. Thus increasing MRR by 4 times than conventional cutter.

Share

| Industry | Engineering |

|---|---|

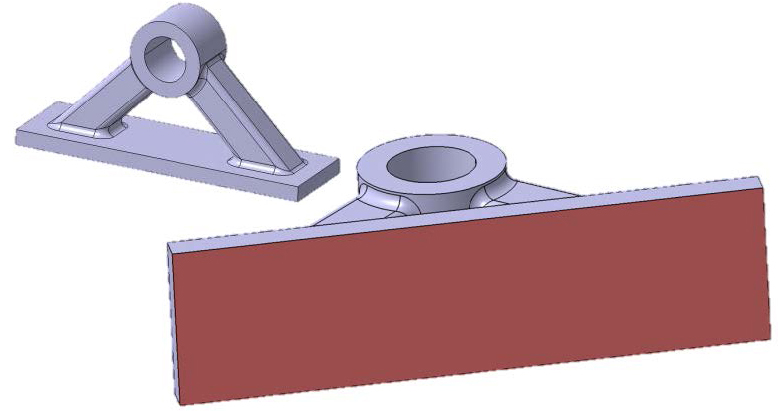

| Component | Bracket |

| Material ISO code |

|

| Work material | FCD700 |

| Machine(spindle type) | Horizontal Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoPent |

| TSR No. | 268M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEN09R125M38.1-06 | Φ80-z=5 |

| Cutting diameter | 125 | 80 |

| Insert | PNCU0905GNER-MJ | TPCH43R… (ISO) |

| Number of cutting edges | 6 | 5 |

| Grade | AH1215 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 188 | 126 |

| Feed per tooth f/z (mm/t) | 0.3 | 0.14 |

| Feed speed Vf (mm/min) | 862 | 351 |

| Depth of cut ap (mm) | 1 | 1 |

| Width of cut ae (mm) | 100 | 60 |

| Coolant | Wet (Internal) | Wet (Internal) |