TungMeister VBB – Injection Mold – AH725

IMPROVED TOOL LIFE

Extended tool life

- AH750’s excellent wear and fracture resistance prolongs the tool life by 1.3 times against the competitor’s.

Improved surface finish

- TungMeister prevents the head from chipping or/and fracture due to the outstanding wear and fracture resistance, leading to excellent surface finish.

Quick tool change

- Because all the heads in TungMeister series can be easily attached to shanks only by screwing in itself, the tool changing can be done quickly. Also, there is no need to worry about dropping the clamp screw when changing it on a machine.

Share

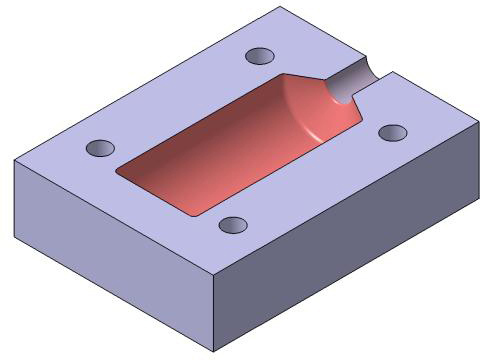

| Industry | Die & Mold |

|---|---|

| Component | Injection Mold |

| Material ISO code |

|

| Work material | Steel alloy |

| Machine(spindle type) | Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Profiling |

| Product name | TungMeister |

| TSR No. | 260M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | VSSD12L070S08-C | Φ12-Z=2 |

| Cutting diameter | 12 | 12 |

| Insert | VBB120L12.0-BM-02S08 | Φ12 insert |

| Number of cutting edges | 2 | 2 |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 180 | 180 |

| Feed per tooth f/z (mm/t) | 0.2 | 0.2 |

| Feed speed Vf (mm/min) | 2000 | 2000 |

| Depth of cut ap (mm) | 0.3 | 0.3 |

| Width of cut ae (mm) | 2 | 2 |

| Coolant | Dry | Dry |