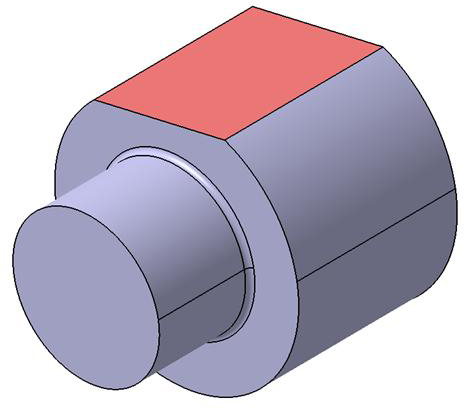

DoFeedQuad – Cover for Ship Part – AH130

IMPROVED PRODUCTIVITY

Improved productivity

Nitriding steel machining have a tendency of chip welding on cutting edge. However because of DoFeedQuad’s sharper cutting edge than competitor and because SQMU inserts are treated with PremiumTec technology it works excellent at higher cutting conditions without much welding.

Maintains workpiece temperature

Since DoFeedQuad have low cutting resistance workpiece does not get heated much after machining compared to Competitor’s cutter.

Share

| Industry | Heavy |

|---|---|

| Component | Cover for Ship Part |

| Material ISO code |

|

| Work material | SACM645 |

| Machine(spindle type) | Horizontal Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoFeedQuad |

| TSR No. | 246M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXQ12R125M38.1-07 | High feed cutter |

| Effective number of teeth | 7 | 6 |

| Cutting diameter | 125 | 125 |

| Insert | SQMU1206ZSR-MJ | SNMU insert |

| Number of cutting edges | 8 | 8 |

| Grade | AH130 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (mm/min) | 150 | 100 |

| Feed per tooth f/z (mm/t) | 0.56 | 0.45 |

| Feed speed Vf (mm/min) | 1497 | 685 |

| Depth of cut ap (mm) | 1 | 1 |

| Width of cut ae (mm) | 85 | 85 |

| Coolant | Dry | Dry |