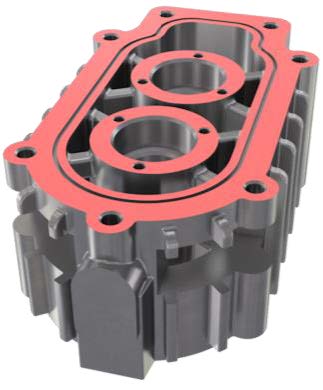

DoOcto – Compressor Part – AH120

HIGH ECONOMICAL & PRODUCTIVE MILLING OF CAST IRON

Economical advantage

- Current competitor insert offers 4 corners per insert. DoOcto offers 16 corners per insert, hence is extremely economical.

High density inserts drastically improves productivity

- DoOcto offers denser pitched cutter bodies than competitor, thus improving productivity even at lower feed & achieve better surface finish.

Share

| Industry | Engineering |

|---|---|

| Component | Compressor part |

| Material ISO code |

|

| Work material | Gray Cast Iron |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoOcto |

| TSR No. | 230M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TAN07R160M40.0A22W | Face mill cutter |

| Effective number of teeth | 22 | 12 |

| Cutting diameter | 160 | 160 |

| Insert | ONHU0705ANPN-ML | LN type insert |

| Number of cutting edges | 16 | 4 |

| Grade | AH120 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 215 | 215 |

| Feed per tooth f/z (mm/t) | 0.04 | 0.06 |

| Feed speed Vf (mm/min) | 377 | 308 |

| Depth of cut ap (mm) | 0.3 | 0.3 |

| Width of cut ae (mm) | 50 | 50 |

| Coolant | Wet (Water Soluble) | Wet (Water Soluble) |