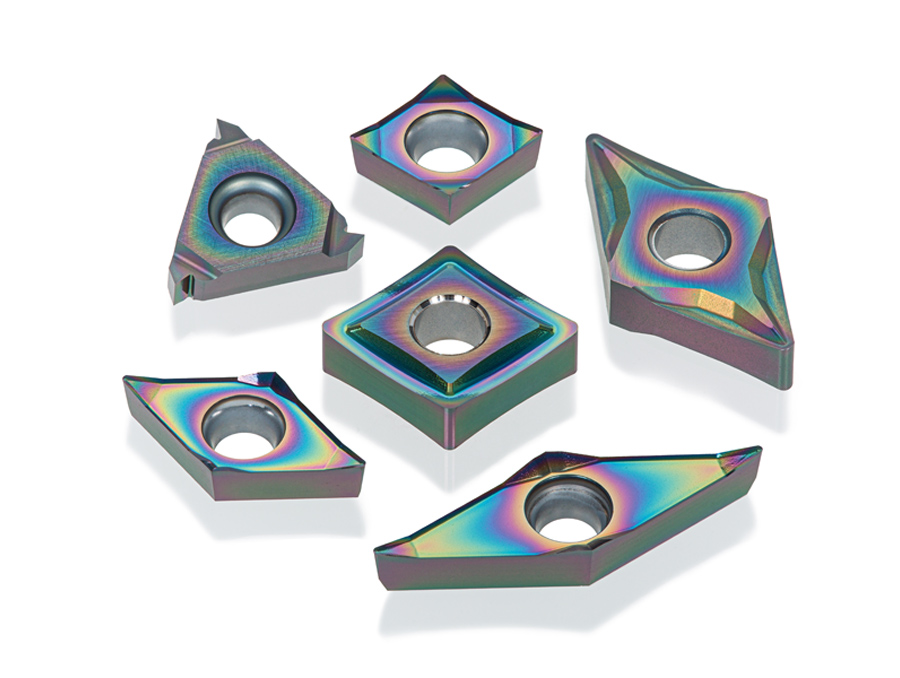

DS2005-Semiconductor parts-DS2005

Excellent built-up edge resistance and high surface quality

Tungaloy original DLC coating grade, DS2005 for non-ferrous alloys

- Excellent built-up edge resistance achieves high quality glossy machined surface.

- The coating with high hardness and excellent heat resistance reduce wear.

- Outstanding coating adhesion technology provides stable and reliable machining.

We tested the DS2005 with the aim of improving tool costs and extending tool life. The results showed that it had a tool life 1.5 times longer than conventional products, while maintaining the same level of surface quality as conventional products and achieving stable machining.

Share

| Industry | Engineering |

|---|---|

| Component | Semiconductor Components |

| Material ISO code |

|

| Work material | Copper alloy |

| Machine(spindle type) | CNC Lathe |

| Tool family | Turning |

| Tool category | External & Face turning |

| Product name | DS2000 |

| TSR No. | 5491T |

Tool

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Holder | Standard tool holder | Standard tool holder |

| Insert | CNGG120408-28 | CNMG120408-** |

| Edges par insert | 4 | 4 |

| Grade | DS2005 | Cemented carbide grade |

Tool life

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 300 | 200 |

Cutting conditions

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 270 | 270 |

| Feed f (mm/rev) | 0.15 | 0.15 |

| Depth of cut ap (mm) | 1 | 1 |

| Depth (mm) | 1 | 1 |

| Coolant | Wet | Wet |