Boost accuracy and reduce cycle time with DeepTriDrill

Deep hole drilling in automotive components like shock absorber piston rods demands precision, stability, and high throughput. Conventional solid gun drills often struggle with chip evacuation and hole straightness, leading to costly rework and downtime.

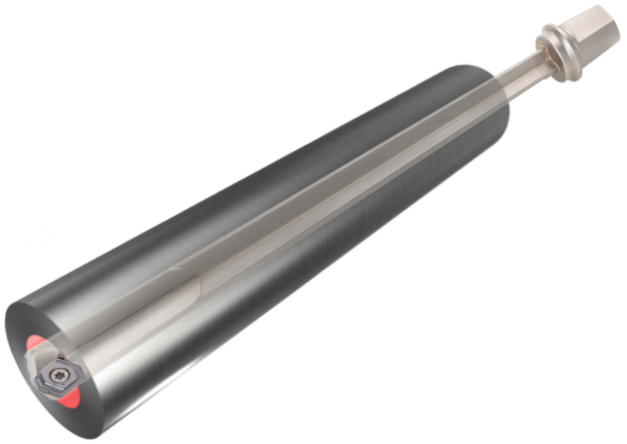

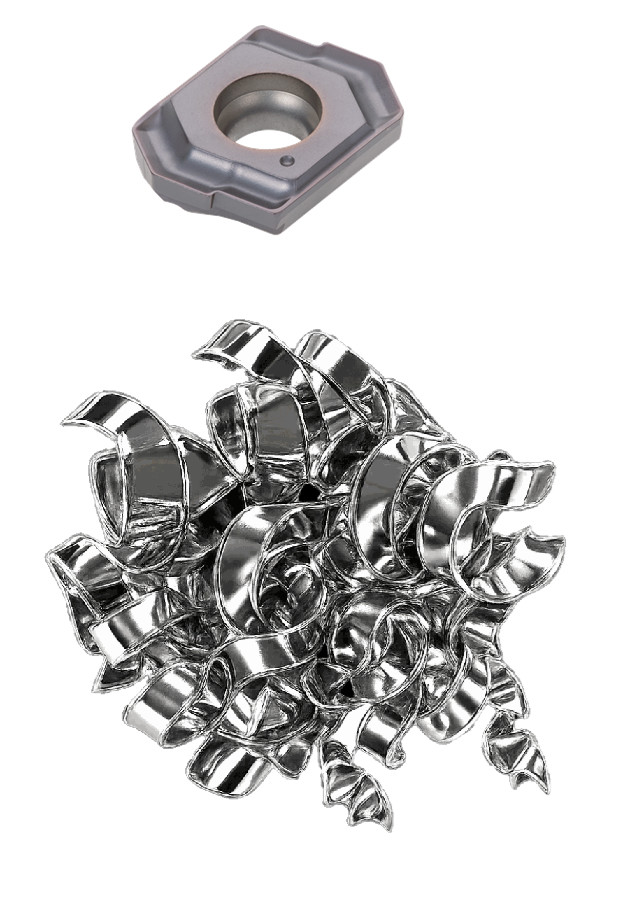

DeepTriDrill addresses these challenges with optimized geometry and coolant delivery for stable drilling and reduced whipping. Tested on S45C material, it demonstrated significant productivity gains and consistent bore quality, even at depths of 246.9 mm.

Hole straightness maintained for accuracy and reliability

Recommended cutting speeds: 90–110 m/min with feed rates up to 0.12 mm/rev

Coolant pressure at 25 Bar ensures effective chip evacuation

Extended tool life with AHM9130 grade inserts and precision guide pads

Proven performance in high-volume automotive applications

This solution can help reduce cycle time and cost per hole while improving process stability. Request a demo or get a quote today.