NTK Ceramatic – Aerospace parts – SX9

NTK Ceramatic – Aerospace parts – SX9

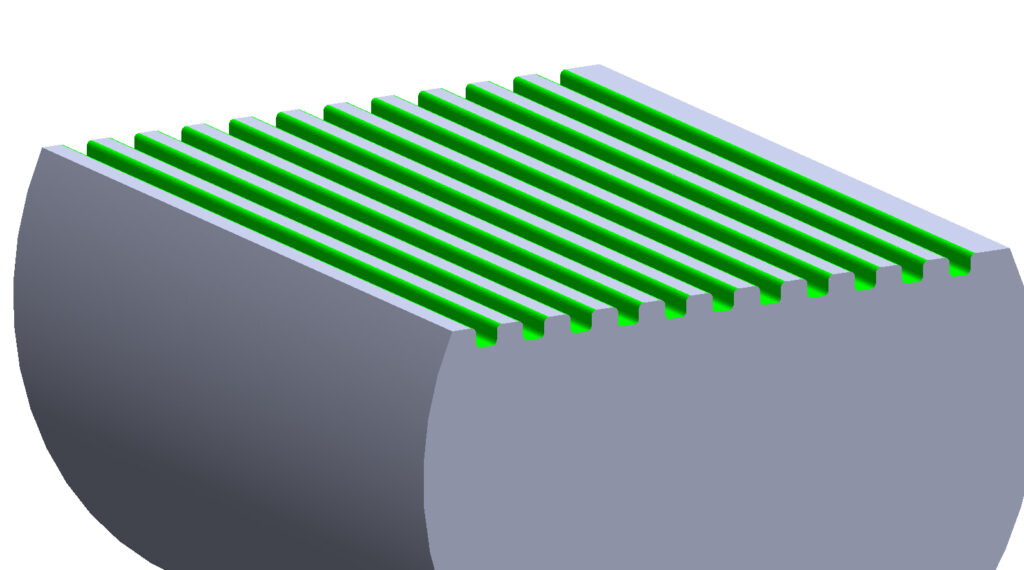

By using the SX9 ceramic end mill, high-speed machining of heat-resistant alloys became possible. Compared to competing products, the cycle time was reduced to 1/26, resulting in a significant improvement in machining efficiency.

Share

| Industry | Aerospace |

|---|---|

| Component | Aerospace parts |

| Material ISO code |

|

| Work material | Inconel718 |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | CERAMATIC |

| TSR No. | 5468M |

Tool

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Insert | RCEM120H4R150S | Φ12 Endmill |

| Grade | SX9 | Carbide |

Cutting conditions

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 650 | 37 |

| Feed f (mm/rev) | 0.2 | 0.1 |

| Depth of cut ap (mm) | 0.5 | 0.5 |

| Width of cut ae (mm) | 8 | 8 |

| Coolant | DRY | DRY |