TungSix-Drill – Construction Equipment Part – AH9030

IMPROVED TOOL LIFE

- While the competitor requires Step feed drilling, TungSix-Drill ensures outstanding chip control without Step feed. This leads to a drastic reduction in machining time.

- AH9030’s excellent oxidation resistance provides long tool life even when machining with external coolant. (Cutting edges usually wear out fast with external coolant because of the increase in temperature.)

- TungSix-Drill significantly reduces tool costs due to the combination of 6 cutting edges and AH9030’s high wear resistance.

Share

| Industry | Heavy |

|---|---|

| Component | Construction machine part |

| Material ISO code |

|

| Work material | High manganese cast steel |

| Machine(spindle type) | Vertical Machining Center |

| Tool family | Holemaking |

| Tool category | Drilling |

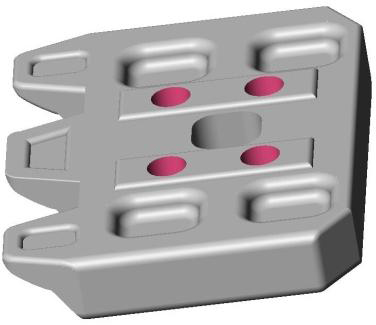

| Product name | TungSix-Drill |

| TSR No. | 121D |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TDS340F32-3 | Indexable drill |

| Insert | WWMU11X512R-DJ | Square type insert |

| Grade | AH9030 | PVD |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (m/insert) | 33 | 16 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Tool diameter DC (mm) | 34 | 34 |

| Hole depth H (mm) | 47 | 47 |

| Cutting speed V/c (m/min) | 110 | 85 |

| Feed f (mm/rev) | 0.13 | 0.16 (need step feed) |

| Feed speed Vf (mm/min) | 134 | 127 |

| Coolant | Water soluble(External) | Water soluble(External) |