IMPROVE TOOL COST AND SURFACE OUALITY

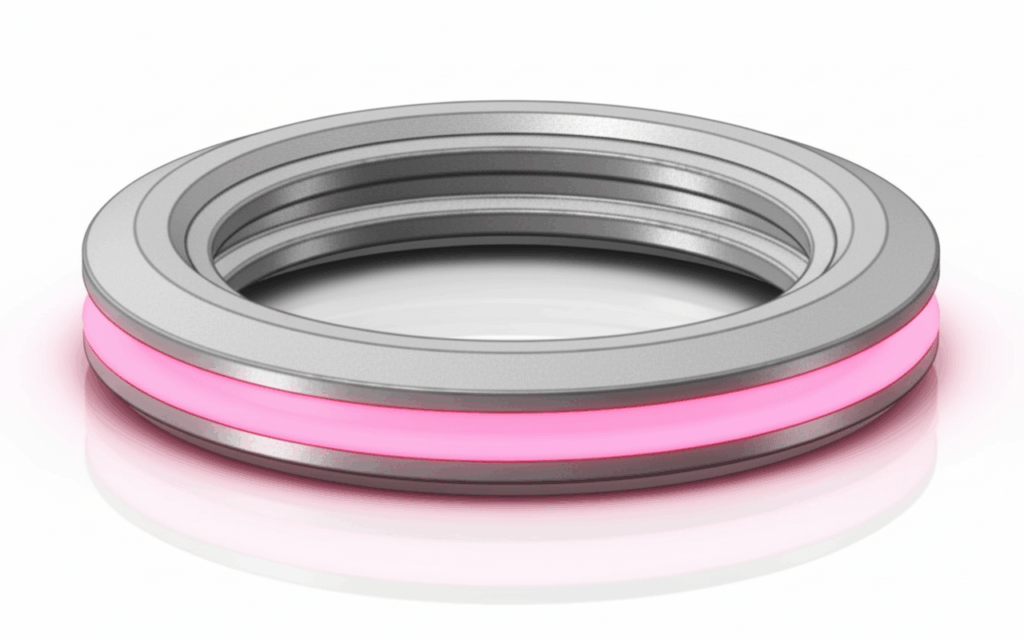

In external grooving of high-tensile strength steel bearings for the aerospace sector, conventional tools often experienced chatter and inconsistent tool life, resulting in rough surfaces and frequent insert changes.

By adopting Tungaloy's TetraForce-Cut with grade AH8005, featuring a highly rigid insert clamping system and a PVD coating optimized for steel machining, the process achieved stable, chatter-free operation and produced consistently superior surface finishes.

As a result, tool life was stabilized at 15 parts per cutting edge, representing a significant improvement over previous solutions and contributing to higher operational efficiency.