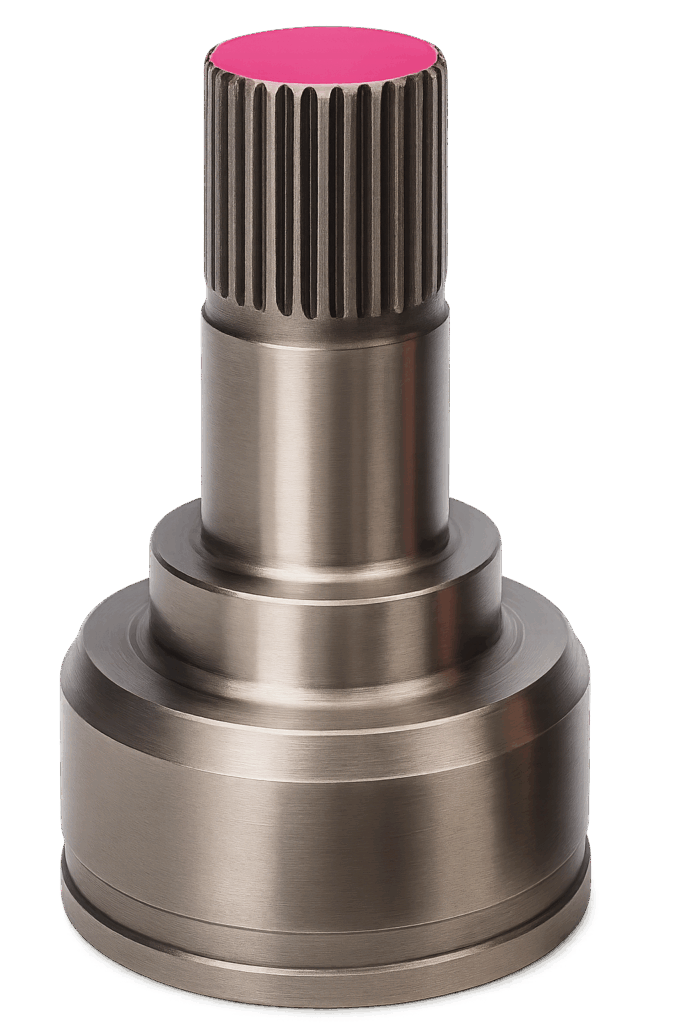

TetraForce-Cut – Constant Velocity Joint – AH6235

IMPROVE TOOL LIFE

In parting-off of constant velocity joint (CVJ) intermediate shafts made from SCM415(H), conventional tools were challenged by rapid tool wear, limiting production efficiency to just 300 parts per cutting edge.

By introducing Tungaloy’s TetraForce-Cut with AH6235 grade, designed for high stability and superior wear resistance in tough steel applications, the customer achieved dramatically longer tool life.

The solution enabled machining of up to 1,000 parts per edge—over three times the previous result—significantly reducing insert changes and overall tooling costs.

Share

| Industry | Automotive |

|---|---|

| Component | Constant Velocity Joint |

| Material ISO code |

|

| Work material | SCM415(H) |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | TetraForce-Cut |

| TSR No. | 121247G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | STCL2525-27 | 25x25 shank |

| Insert | TCG27-230-050G36 | 3 corner insert |

| Edges par insert | 4 | 3 |

| Cutting width | 2.3 | 2.3 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 1000 | 300 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 110 | 110 |

| Feed f (mm/rev) | 0.15 | 0.15 |

| Depth (mm) | 3.09 | 3.09 |

| Coolant | Compressed air | Compressed air |