AddForceCut – PIN – SH7025

IMPROVE CONVENIENCE OF TOOL MANAGEMENT

In external grooving of SUS304 pins on a dedicated machine, the previous brazed tool limited operational efficiency, especially since tool management efficiency could not be increased due to equipment constraints.

By switching to Tungaloy's AddForceCut with the SH7025 grade, which is engineered for reliable performance in stainless steel machining, the user achieved stable and problem-free processing with improved work efficiency.

Share

| Industry | Automotive |

|---|---|

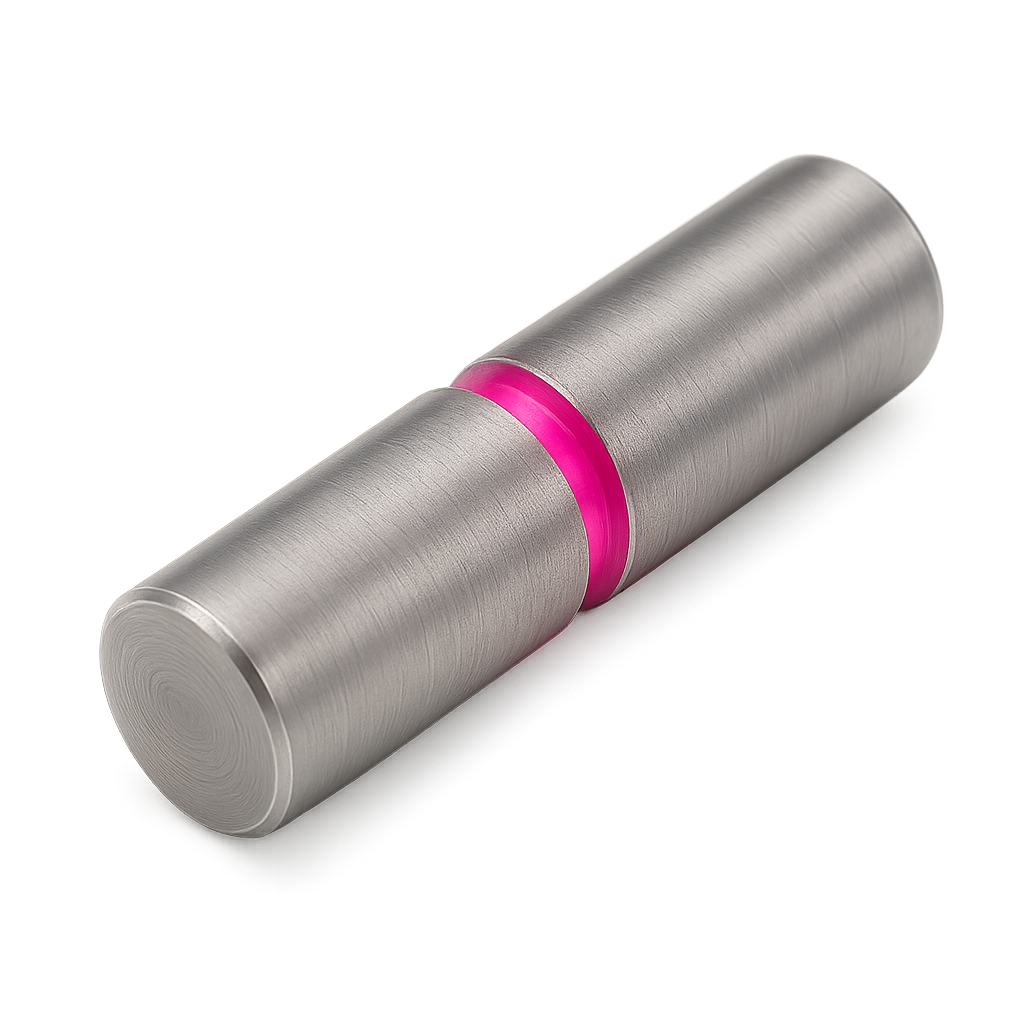

| Component | Pin |

| Material ISO code |

|

| Work material | SUS304 |

| Machine(spindle type) | Dedicated Machine |

| Tool family | Grooving |

| Tool category | External grooving |

| Product name | AddForceCut |

| TSR No. | 122122G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | JSXXL1010H05 | Blazed tool |

| Insert | JVGN20L075F000 | |

| Edges par insert | 1 | 1 |

| Cutting width | 0.75 | 0.75 |

| Grade | SH7025 | Uncoated carbide |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 5000 | 5000 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 30 | 30 |

| Feed f (mm/rev) | 0.03 | 0.03 |

| Depth (mm) | 0.9 | 0.9 |

| Coolant | External | External |