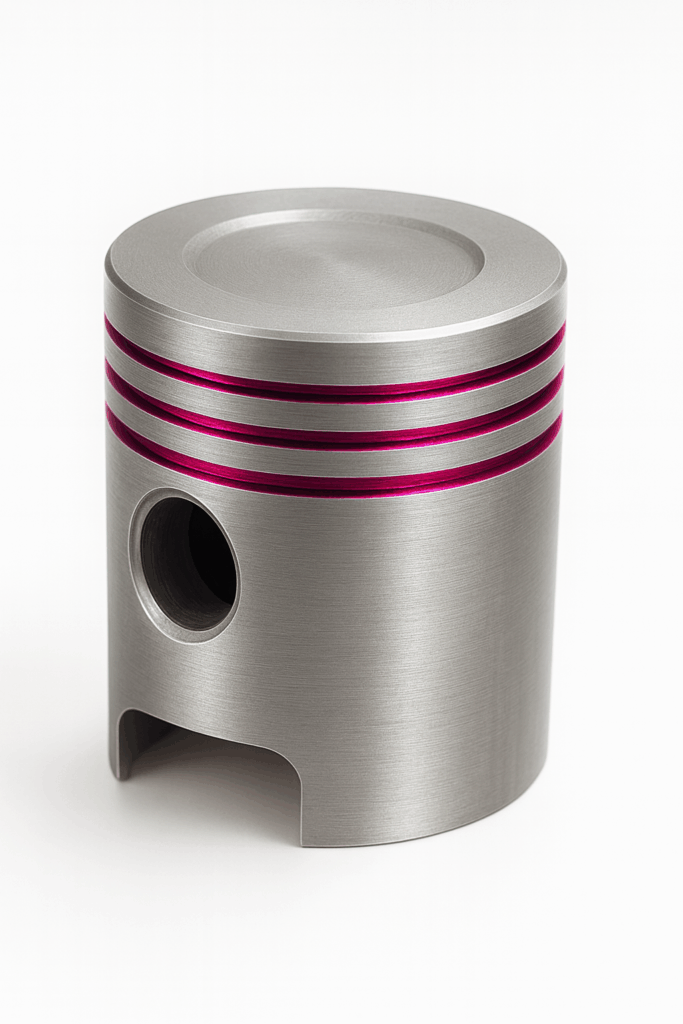

IMPROVE TOOL LIFE

During external grooving of pistons made from SCM415 steel, inconsistent tool life with the previous tool led to frequent insert changes and unstable production.

By adopting Tungaloy’s TungCut system with grade AH7025, which features excellent wear resistance and stable performance in steel machining applications, the shop achieved both longer and more consistent tool life.

As a result, the number of parts processed per cutting edge tripled, with stable operation at 150 pieces per edge compared to just 50 with the previous solution. This significant improvement ensured greater process reliability and reduced downtime for insert replacement.