IMPROVE PRODUCTIVITY AND TOOL LIFE

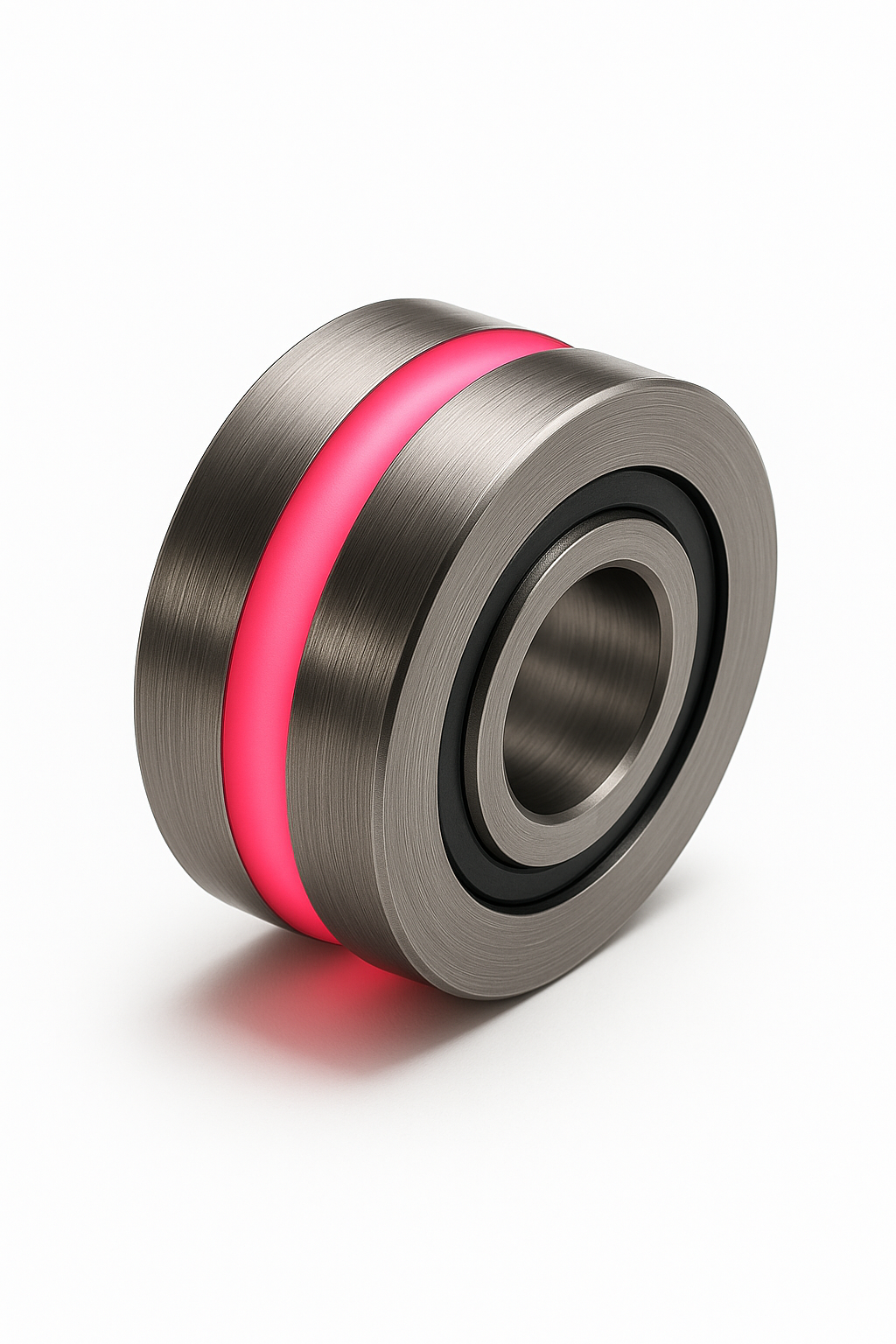

In external grooving of SKD11 rollers on a CNC lathe, the conventional tool struggled to deliver satisfactory tool life and productivity when machining this hardened material.

By introducing Tungaloy’s CTER12-4T25 holder with STR400-HP insert in BXA10 grade—a coated PCBN grade known for excellent chipping resistance and stable performance in hard part turning—both tool life and machining efficiency improved dramatically.

The number of parts produced per cutting edge increased to 5, representing a 250% improvement, while overall productivity rose by over 460% compared to the previous setup. The customer was very satisfied with these significant gains.