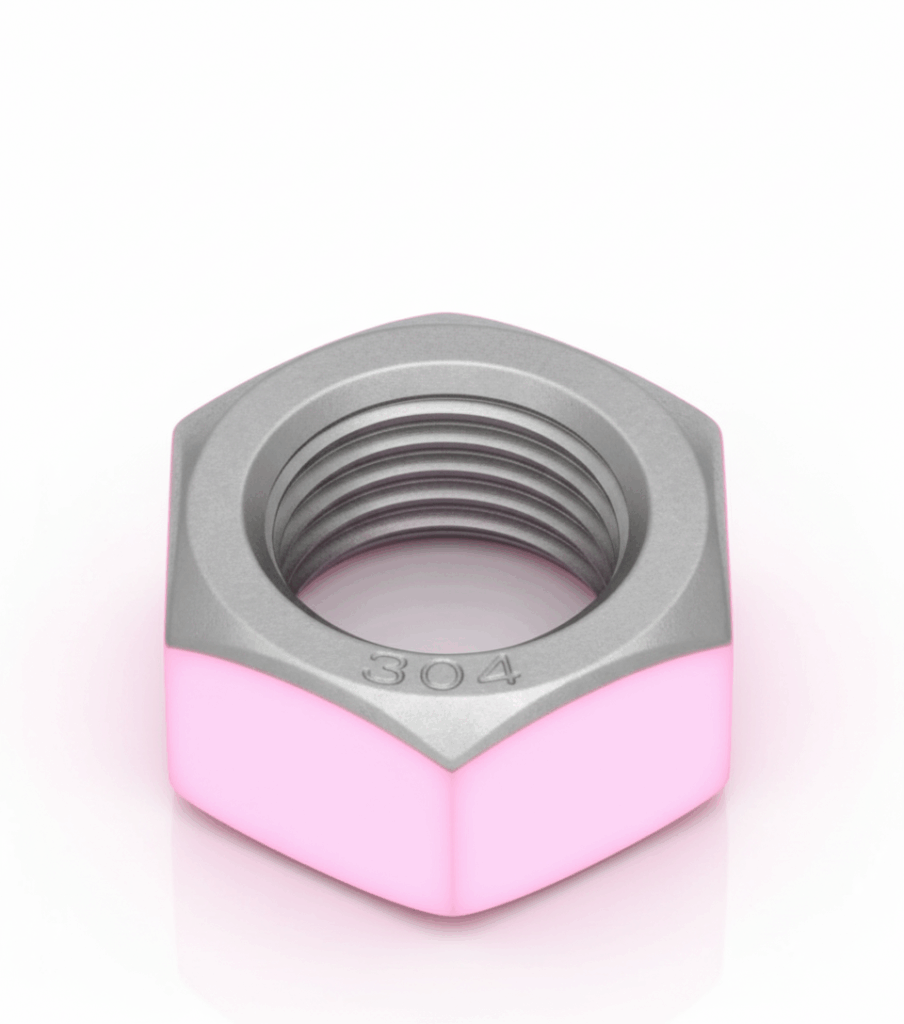

ShredMeister, Nut, AH725

IMPROVED TOOLLIFE & PRODUCTIVITY

The workpiece was being machined under weak clamping conditions. Previously, roughing was performed slowly with a high-speed steel (HSS) roughing end mill. However, the ShredMeister enabled stable machining with lower cutting resistance, resulting in three times higher machining efficiency and double the tool life.

Share

| Industry | Engineering |

|---|---|

| Component | Nut |

| Material ISO code |

|

| Work material | 304 |

| Machine(spindle type) | Vertical Machining Center Small(#30,HSK40) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | ShredMeister |

| TSR No. | 5453M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TECR120B4MF-26W12-83 | HSS Roughing endmill |

| Number of teeth | 4 | 4 |

| Cutting diameter | 12 | 12 |

| Overhang (mm) | 40 | 55 |

| Grade | AH725 | HSS |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 79 | 49 |

| Feed per tooth f/z (mm/t) | 0.1 | 0.08 |

| Feed speed Vf (mm/min) | 838 | 416 |

| Depth of cut ap (mm) | 6 | 6 |

| Width of cut ae (mm) | 2 | 2 |

| Coolant | External | External |