NTK PVD Carbide TMV Chipbreaker – Railway components – 650

NTK PVD Carbide TMV Chipbreaker - Railway components - 650

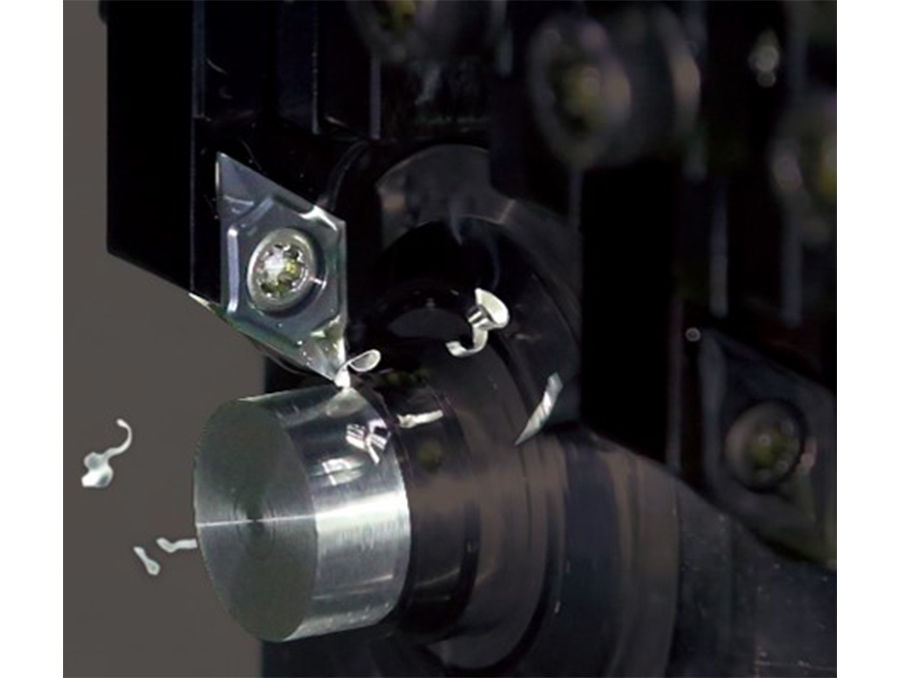

By using TMV-650, the test showed excellent surface finish and extended tool life by 1.5 times compared to the competitor. In addition, NTK’s TMV geometry provided stable cutting, reduced vibration, and superior chip control, contributing to improved productivity and consistent quality in finishing operations.

Share

| Industry | Railway |

|---|---|

| Component | Railway components |

| Material ISO code |

|

| Work material | Inconel 718 |

| Machine(spindle type) | Swiss Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | Miniature - TMV Chipbreaker |

| TSR No. | 5433T |

Tool

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Insert | DCGT11T304MRTMV | DCGT11T304 |

| Grade | 650 | PVD Coated Carbide |

Tool life

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 85 | 55 |

Cutting conditions

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 30 | 30 |

| Feed f (mm/rev) | 0.1 | 0.1 |

| Depth of cut ap (mm) | 0.08 | 0.08 |

| Number of pass | 2 | 2 |

| Coolant | WET | WET |