VariableMeister- Mold for automotive case- AH710

IMPROVED PRODUCTIVITY

When attempting to increase machining efficiency on high-hardness materials of 64 HRC, competitor endmills experienced chipping, making it impossible to improve productivity.

VariableMeister 7-flute endmill offers superior chipping resistance, enabling high-feed machining at low speeds and achieving 1.5 times the productivity compared to competitor products.

Tool life was also equal to or greater than that of the competitor product, which led to its adoption.

Share

| Industry | Automotive |

|---|---|

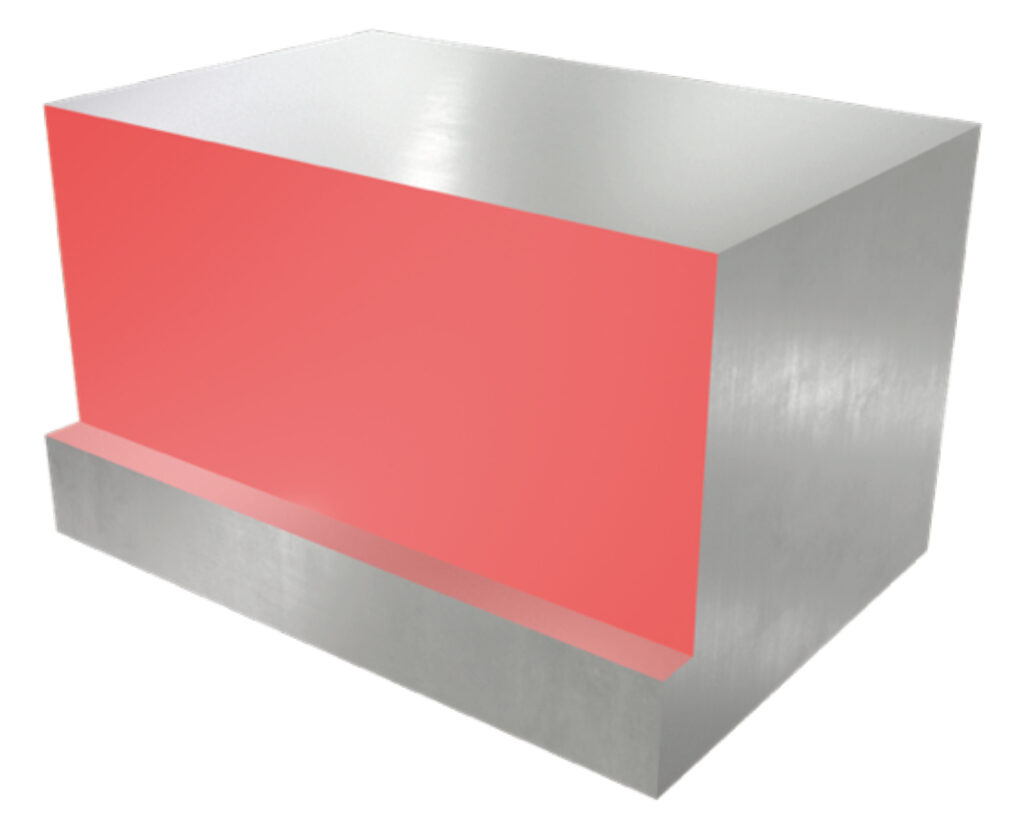

| Component | Mold |

| Material ISO code |

|

| Work material | HAP40 |

| Material hardness | 64 HRC |

| Machine(spindle type) | Vertical Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | VariableMeister |

| TSR No. | 5404M |

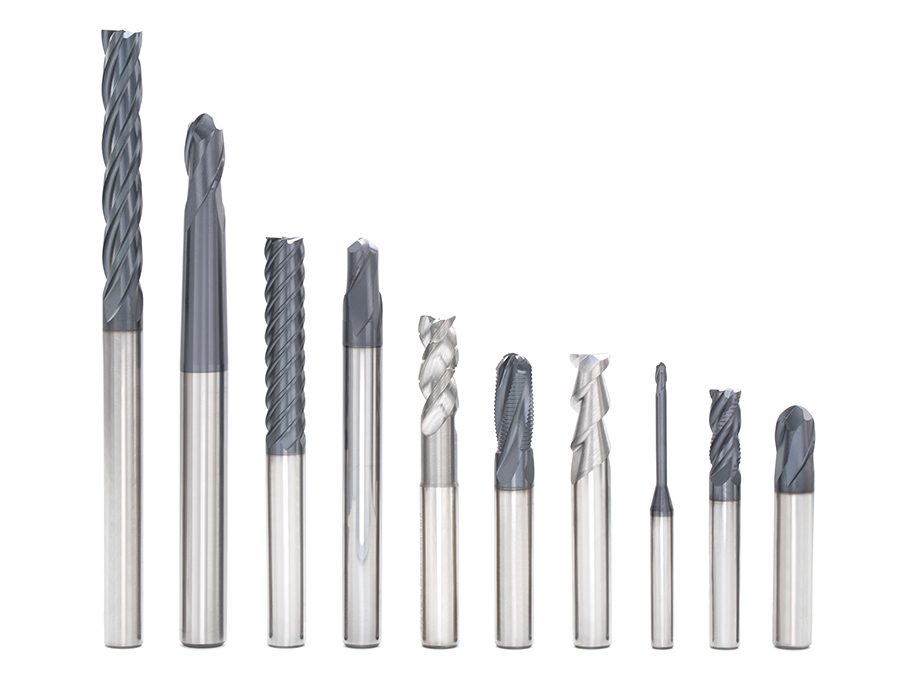

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEC120H7-24C12CFM83AH710 | |

| Number of teeth | 7 | 6 |

| Cutting diameter | 12 | 12 |

| Grade | AH710 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 26 | 41 |

| Feed per tooth f/z (mm/t) | 0.04 | 0.02 |

| Feed speed Vf (mm/min) | 193 | 131 |

| Depth of cut ap (mm) | 12 | 12 |

| Width of cut ae (mm) | 0.05 | 0.05 |

| Coolant | External | External |