MillQuadFeed15 – Inconel cladding machining – Flat Top Inserts

IMPROVE TOOLLIFE & PRODUCTIVITY

For shoulder milling of an Inconel 625 cladded valve body, MillQuadFeed Flat-Top inserts were proposed as an alternative to the competitor’s tool. They enabled stable high-feed machining, reducing cycle time by 60%. In addition, tool life was extended by 1.4 times, achieving both higher productivity and longer tool life compared to the competitor’s tool.

Share

| Industry | Oil & Gas |

|---|---|

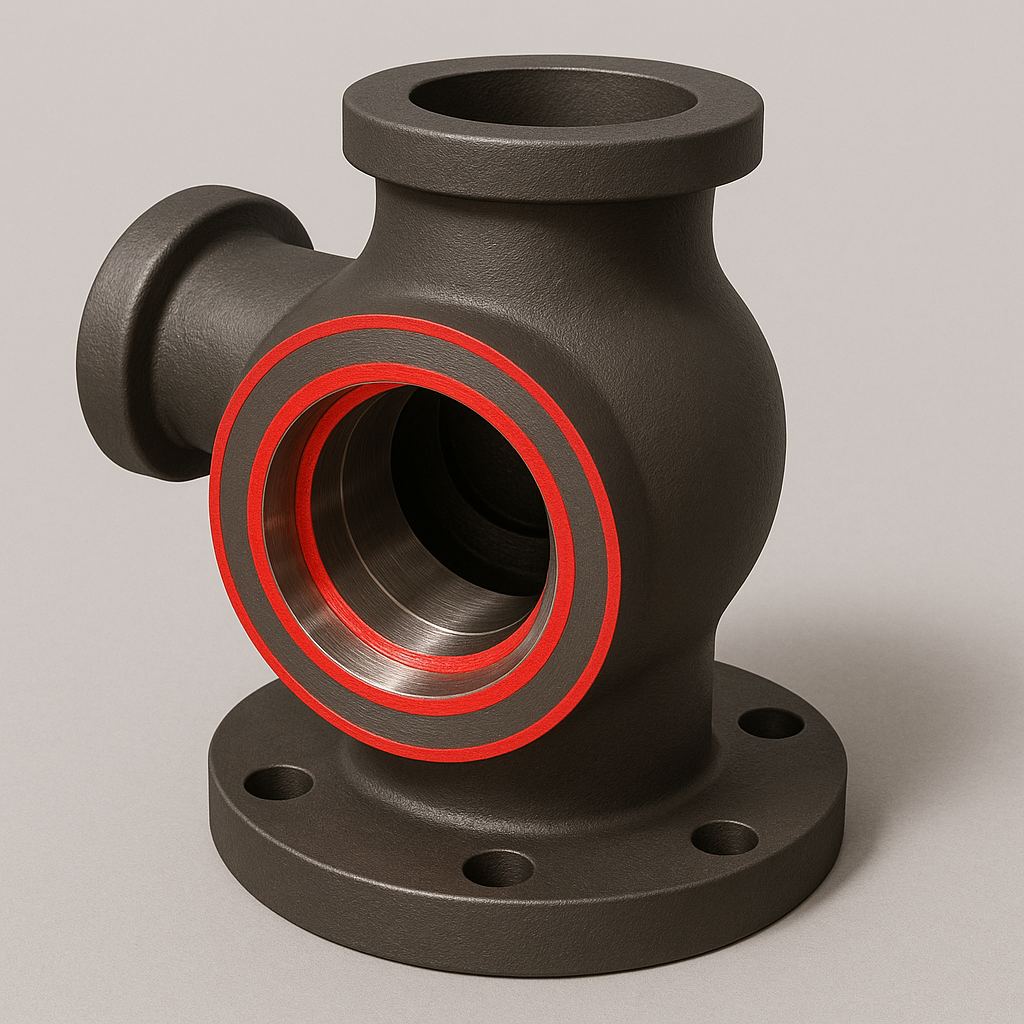

| Component | Valve body |

| Material ISO code |

|

| Work material | Inconel 625 |

| Machine(spindle type) | Horizontal Machining Center Large(#50,HSK100) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | MillQuadFeed |

| TSR No. | 5391M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TXSW15M080B27.0R05 | Shoulder milling cutter |

| Number of teeth | 5 | 4 |

| Cutting diameter | 80 | 63 |

| Insert | SWMW1506USR | Posi 2 corner |

| Number of cutting edges | 4 | 2 |

| Grade | AH8015 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 30 (98.4 sfm) | 35 (114.8 sfm) |

| Feed per tooth f/z (mm/t) | 0.8 (.0315 ipt) | 0.4 (.0157 ipt) |

| Feed speed Vf (mm/min) | 480 (18.9 ipm) | 240 (9.4 ipm) |

| Depth of cut ap (mm) | 0.7 (.0276") | 0.5 (.0197") |

| Coolant | External coolant | External coolant |