FinishMeister -Valve -AH725

IMPROVED PRODUCTIVITY & TOOL LIFE

Due to the low clamping rigidity of the workpiece, turning could not be performed, and conventionally machining was done using a 4-flute solid carbide endmill, but productivity could not be improved.

With FinishMeister, the wavy cutting edges reduce cutting resistance, enabling a threefold increase in machining efficiency. In addition, even as wear progresses, vibration is suppressed, resulting in a 15-fold extension of tool life.

Share

| Industry | Automotive |

|---|---|

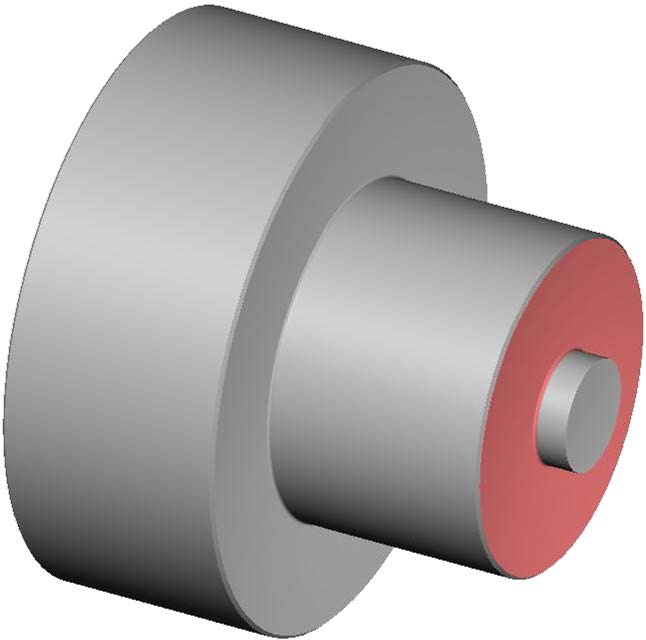

| Component | Valve |

| Material ISO code |

|

| Work material | AISI 316 |

| Machine(spindle type) | Multi-Tasking Machine |

| Tool family | Milling |

| Tool category | Shoulder milling |

| Product name | FinishMeister |

| TSR No. | 5380M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEFS120B44-26C12-83 | Solid endmill |

| Number of teeth | 4 | 4 |

| Cutting diameter | 12 | 12 |

| Number of cutting edges | 4 | 4 |

| Grade | AH725 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 60 | 40 |

| Feed per tooth f/z (mm/t) | 0.06 | 0.06 |

| Feed speed Vf (mm/min) | 382 | 255 |

| Depth of cut ap (mm) | 5 | 5 |

| Width of cut ae (mm) | 2 | 1 |

| Coolant | External | External |