AddForceCut – Valve – AH6235

IMPROVE PRODUCTIVITY AND TOOL LIFE

In the parting off process of Valve components made from SUS 316L stainless steel on a CNC lathe, the previous tool struggled with producing long, unbroken chips that impacted process stability and chip evacuation.

By adopting Tungaloy's AddForceCut, featuring a rigid self-clamping system and AH6235 PVD grade optimized for stainless steel, the customer achieved reliable chip breaking and improved machining consistency.

This resulted in a significant productivity increase of over 260% and a 25% enhancement in tool life compared with the previous solution.

Share

| Industry | Engineering |

|---|---|

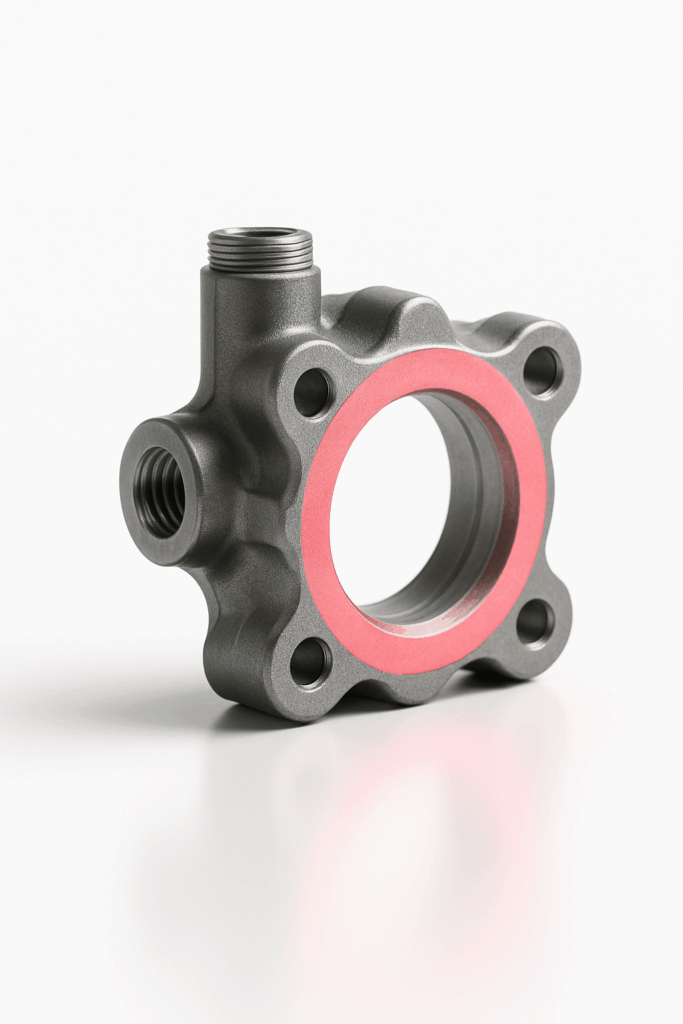

| Component | Valve |

| Material ISO code |

|

| Work material | SUS316L / X2CrNiMo17-12-3 |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | AddForceCut |

| TSR No. | 116886G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | QSP32-3D | Blade |

| Shank | CTBU32-32 | |

| Insert | QGS3-020 | 2 corner insert |

| Edges par insert | 1 | 2 |

| Cutting width | 3 | 3 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 15 | 12 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 80 | 100 |

| Feed f (mm/rev) | 0.1 | 0.03 |

| Depth (mm) | 3 | 3 |

| Coolant | Internal + External | Internal + External |