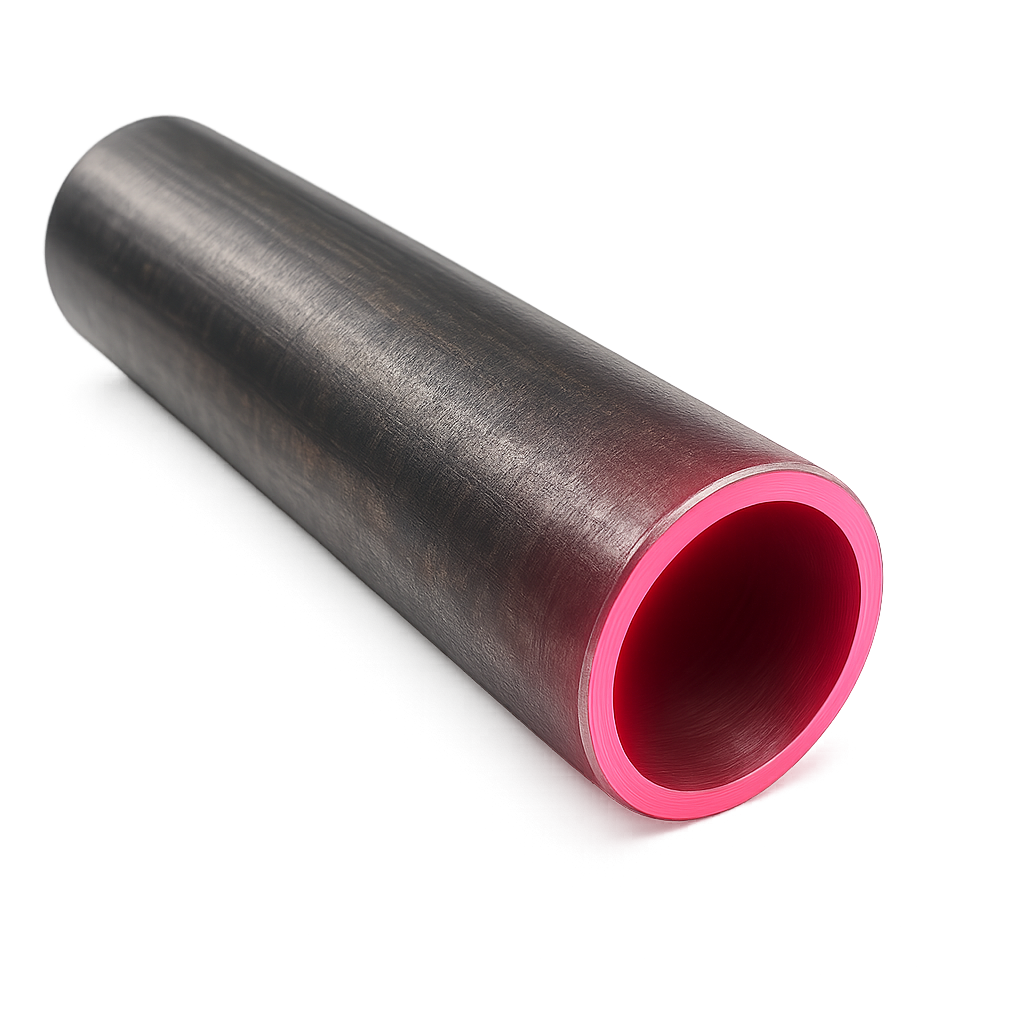

AddForceCut – Tubing Pipe – AH6235

IMPROVE TOOL LIFE

During parting-off operations on oil well tubing pipes made from 13cr alloy, the previous tool exhibited limited tool life and occasional edge chipping, particularly when processing mixed material lots.

By introducing Tungaloy's AddForceCut system equipped with AH6235 grade inserts—recognized for their high hardness and advanced PVD coating that delivers superior wear and fracture resistance—greater stability was achieved in these demanding conditions.

This switch enabled a significant increase in parts processed per cutting edge, extending tool life by approximately 47% compared with the previous solution.

Share

| Industry | Oil & Gas |

|---|---|

| Component | Tubing Pipe |

| Material ISO code |

|

| Work material | 13cr |

| Machine(spindle type) | CNC Lathe |

| Tool family | Grooving |

| Tool category | Parting off |

| Product name | AddForceCut |

| TSR No. | 116150G |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Holder | QSER3232-6T41 | 32x32 shank |

| Insert | QGM6-030 | 1 corner insert |

| Edges par insert | 1 | 1 |

| Cutting width | 6 | 6 |

| Grade | AH6235 | PVD grade |

Tool life

| Tungaloy | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 59 | 40 |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 80 | 80 |

| Feed f (mm/rev) | 0.13 | 0.13 |

| Depth (mm) | 17.3 | 17.3 |

| Coolant | External | External |