DoPent – Heavy Equipment Part – AH3225

IMPROVE PRODUCTIVITY

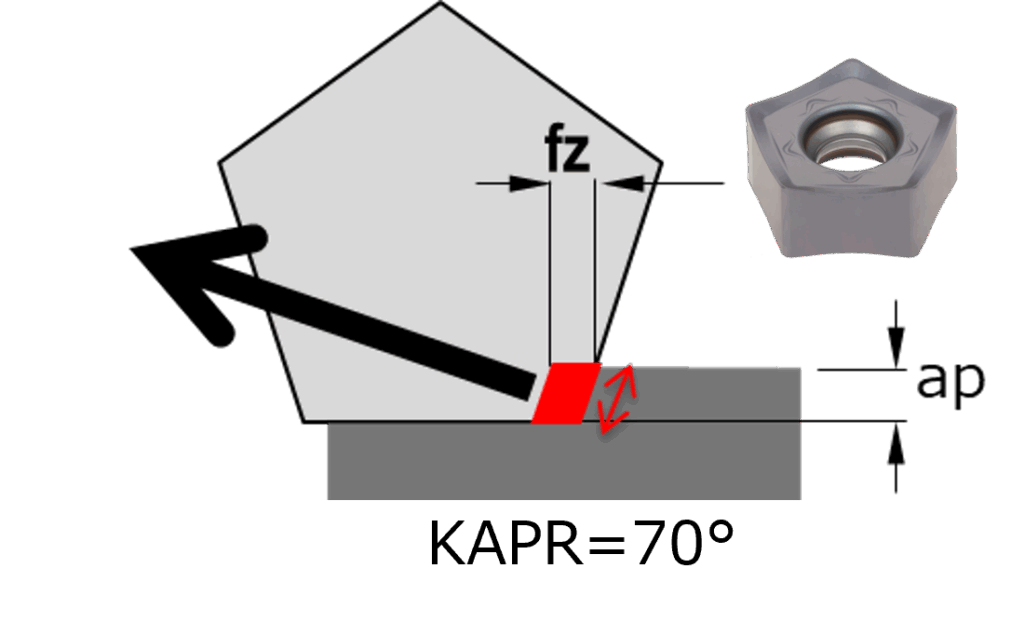

The competitor’s tool pushed too hard on weak parts, making chatter and rough surfaces. DoPent, with a 70-degree angle, pushed less, cut smoother, and gave better surfaces. It also allowed faster cutting, so productivity became 2.4 times higher.

Share

| Industry | Heavy |

|---|---|

| Component | Heavy equipment part |

| Material ISO code |

|

| Work material | S235 |

| Machine(spindle type) | Horizontal Machining Center Middle(#40,HSK63) |

| Tool family | Milling |

| Tool category | Face milling |

| Product name | DoPent |

| TSR No. | 5371M |

Tool

| Tungaloy | Competitor | |

|---|---|---|

| Body | TEN09R100M31.7-08 | 45°Face mill |

| Number of teeth | 8 | 8 |

| Cutting diameter | 100 | 100 |

| Insert | PNMU0905GNEN-MJ | Negative, pentagonal insert |

| Number of cutting edges | 10 | 10 |

| Grade | AH3225 | PVD |

Cutting conditions

| Tungaloy | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 150 (492 sfm) | 125 (410 sfm) |

| Feed per tooth f/z (mm/t) | 0.2 (.008 ipt) | 0.1 (.004 ipt) |

| Feed speed Vf (mm/min) | 764 (30.08 ipm) | 318 (12.52 ipm) |

| Depth of cut ap (mm) | 1.0 (.039") | 1.0 (.039") |

| Width of cut ae (mm) | 90 (3.543") | 90 (3.543") |

| Coolant | Dry | Dry |