NTK PVD carbide TMV Chipbreaker -POM plastic spool- TM4

NTK PVD carbide TMV Chipbreaker -POM plastic spool- TM4

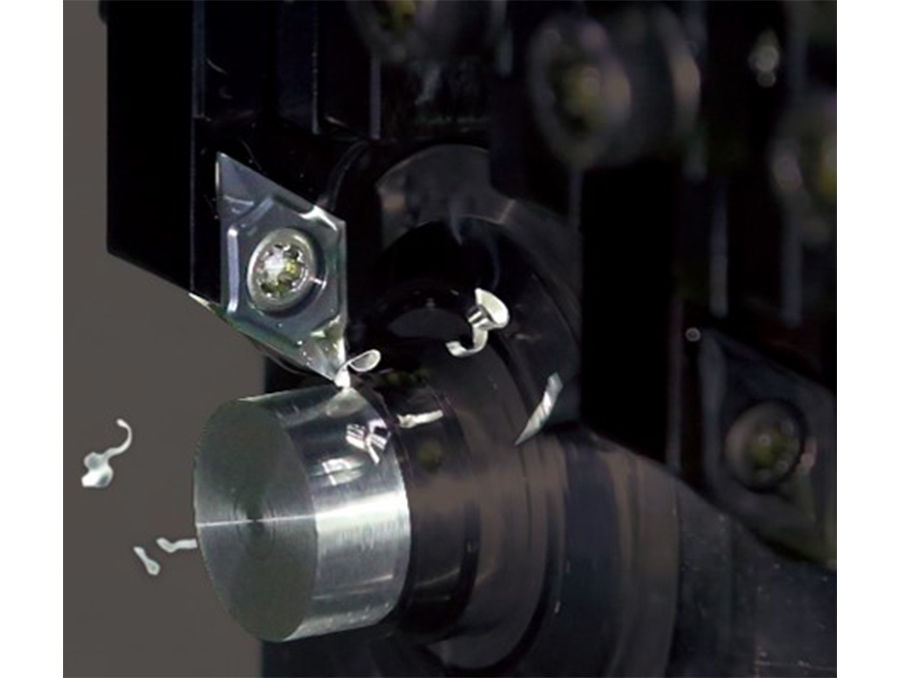

-The existing tool had trouble with chip control when cutting plastic, leading to a 30% defect rate. Also, the existing tool chipped early during vibration cutting. Therefore, vibration cutting could not be used with the existing insert.

-TMV achieved stable machining with vibration cutting and reached 1.2 times longer tool life. Vibration cutting became possible, and short chips from TMV chipbreaker helped achieve 0% defect rate. Surface finish and dimensional accuracy also improved significantly.

Vibration conditions: LFV (MODE 1): D0.5, Q2.0, f0.03

Share

| Industry | Miniature |

|---|---|

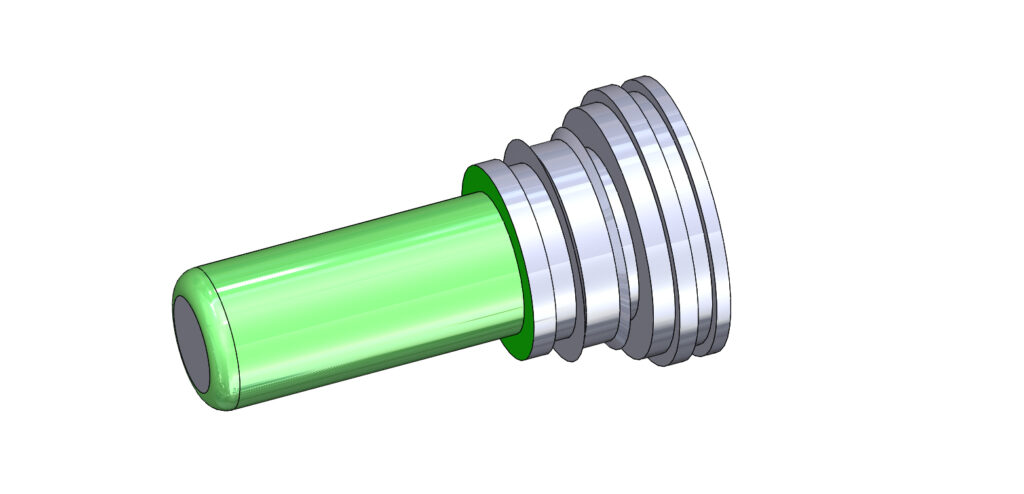

| Component | Spool |

| Material ISO code |

|

| Machine(spindle type) | Swiss Lathe |

| Tool family | Turning |

| Tool category | External turning |

| Product name | Miniature - TMV Chipbreaker |

| TSR No. | 5203T |

Tool

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Insert | DCGT11T302MRTMV | DCGT11T302 |

| Grade | TM4 | Carbide |

Tool life

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Tool life (pcs/edge) | 1500 | 1200 |

Cutting conditions

| Tungaloy - NTK | Competitor | |

|---|---|---|

| Cutting speed V/c (m/min) | 31 | 31 |

| Feed f (mm/rev) | 0.03 | 0.03 |

| Depth of cut ap (mm) | 2.5 | 2.5 |

| Number of pass | 1 | 1 |

| Coolant | WET | WET |